- Joined

- Oct 2, 2016

- Messages

- 9

Hello,

I had my Tree 2UVR head rebuilt ans after re-insalling it on the quill I now have 12-13 thousands of end float in my spindle. Of course I found this out after breaking a carbide cutter. But I'm at a loss as to where the play is at.

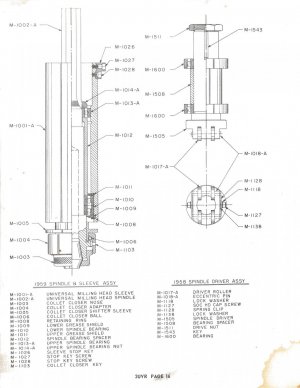

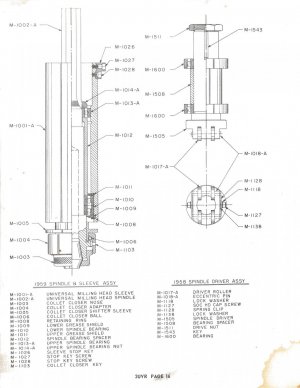

I checked the spindle nut, item M-1014A, it's tight. The only other place I see where the play could come from is between the grease shields and retaining ring? Items M-1011, M-1009, and M-1008 respectively.

If this is the case how do I get to them with the collet closer shifter sleeve, M-1005, in the way?

Any help would be greatly appreciated.

Garrett

I had my Tree 2UVR head rebuilt ans after re-insalling it on the quill I now have 12-13 thousands of end float in my spindle. Of course I found this out after breaking a carbide cutter. But I'm at a loss as to where the play is at.

I checked the spindle nut, item M-1014A, it's tight. The only other place I see where the play could come from is between the grease shields and retaining ring? Items M-1011, M-1009, and M-1008 respectively.

If this is the case how do I get to them with the collet closer shifter sleeve, M-1005, in the way?

Any help would be greatly appreciated.

Garrett