Hi PocoJoe. Great question!

I'm not sure as to getting the DROs setup but here's what worked in shop CNC.

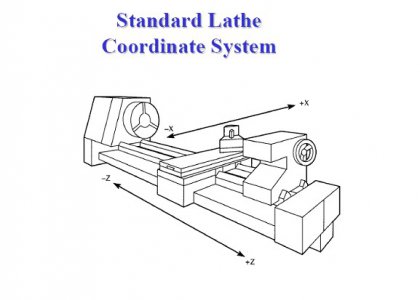

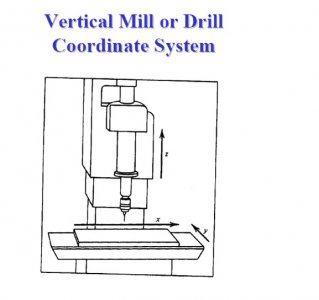

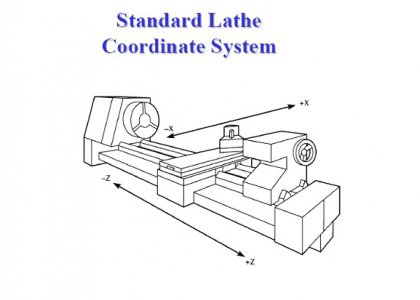

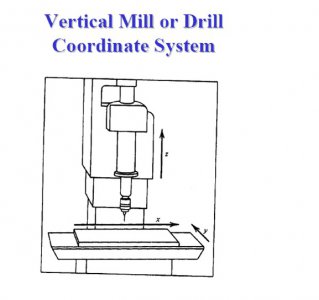

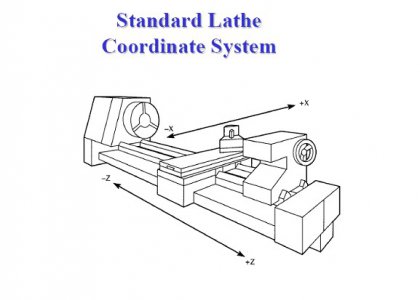

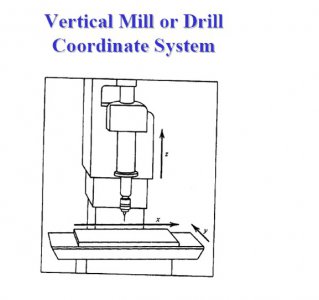

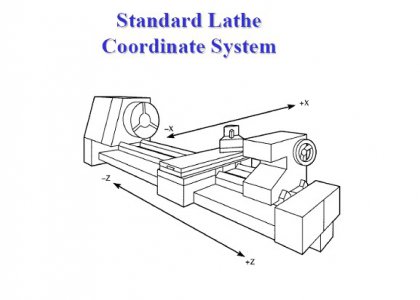

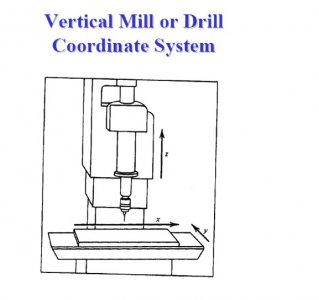

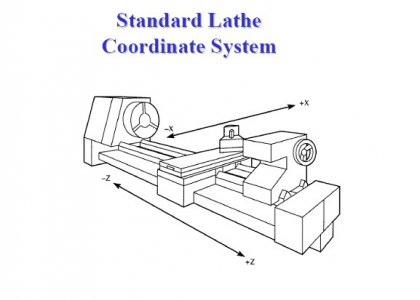

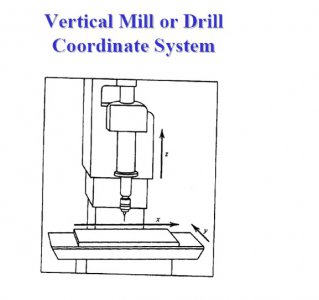

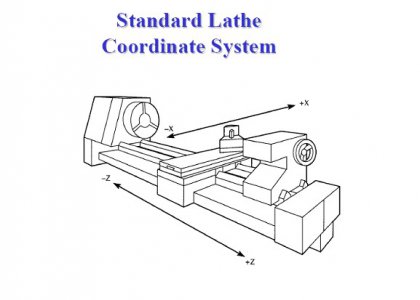

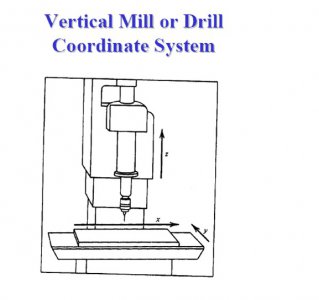

Most CNC machines come with a "machine zero". This seems to be the center of travel on all axes. In other words, as the operator faces the machine the table can travel an equal distance to the left (x-) or right (x+), an equal distance towards the operator (y-) or away from the operator (y+), and the mill spindle can travel towards the table (z-) or away from the table (z+).

The best quick definition for Z-axis I've heard is "the Z is movement of the tool". Works pretty well on mills or lathes.

I use the terminology "towards the operator" because, depending on the 3-in-1 machine you have the column may be to your left attached to the headstock or in front of you, attached to the lathe bed.

For me, when I still had my Smithy Granite, when doing milling I tried to set up the workpiece as close to being centered on "machine zero" as possible. This allowed me plenty of space to work with.

Glad to see you here in Tucson! There's a couple of us on here.