Anyone consider a Striatech DVR motor for a variable speed lathe motor conversion?

striatech.com

striatech.com

They call it a "Switched Reluctance Motor", it seems their motor type is unique. I have one on my Nova Drill press and Rikon Band saw... great for dialing in the right speed and making my band saw go from 100 SFPM for steel, all the way to 1500+ SFPM for wood. I was as in my local hardware store and noticed they were selling the 1.75 HP at a pretty good discount and thought it seems like a decent option for the 1236T lathe I plan to buy.

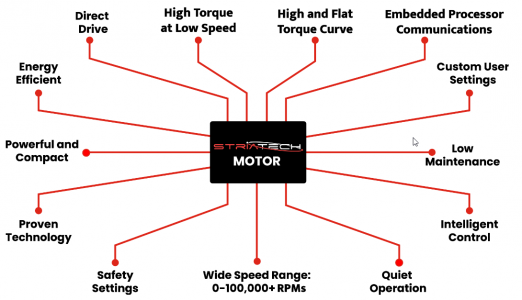

They tout:

- max torque over the entire speed range

- smarts to keep desired RPM constant based on monitoring load (as well as saving power consumption when load is lower)

- and many other things.

They show torque and RPM curves for the 1HP motor... did not find them for the larger motors.

I'm also not sure how much external input signaling you can wire (if any) to these like you can a VFD. For instance, on the 1236T, I would need to send input from the motor control lever on the apron to signal you want to start the lathe and which direction depending on up or down you are moving the lever.

striatech.com - where mind meets motor

Almost Sentient Intuitive Electric MotorsReturn of Investment Within A YearLearn whyIntelligent Motors With Up To 10 Year WarrantyNo brushes. No rotating winding.Learn whyIncredible Energy SavingsUp

They call it a "Switched Reluctance Motor", it seems their motor type is unique. I have one on my Nova Drill press and Rikon Band saw... great for dialing in the right speed and making my band saw go from 100 SFPM for steel, all the way to 1500+ SFPM for wood. I was as in my local hardware store and noticed they were selling the 1.75 HP at a pretty good discount and thought it seems like a decent option for the 1236T lathe I plan to buy.

They tout:

- max torque over the entire speed range

- smarts to keep desired RPM constant based on monitoring load (as well as saving power consumption when load is lower)

- and many other things.

They show torque and RPM curves for the 1HP motor... did not find them for the larger motors.

I'm also not sure how much external input signaling you can wire (if any) to these like you can a VFD. For instance, on the 1236T, I would need to send input from the motor control lever on the apron to signal you want to start the lathe and which direction depending on up or down you are moving the lever.