- Joined

- Mar 14, 2013

- Messages

- 736

Yes, so is mine (except a metal lathe) that I was referring to. My point is that with the mass of the chuck and the work, it can take longer to coast to a stop then for the VFD to decelerate the motor and stop it depending on the settings.

I dont think there is a way, at least not on my FM50.

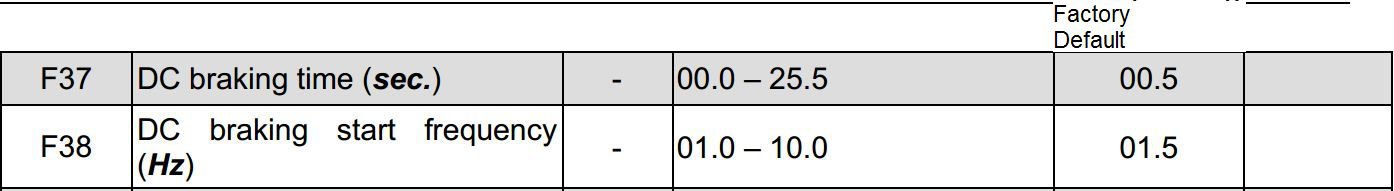

IDK Maybe I'll just leave it alone. I did find a F 37 and F 38, Maybe that is it??

F 37 - DC braking time (sec.) - 00.0 – 25.5 (Default 00.5 )

F38 DC braking start frequency (Hz) - 01.0 – 10.0 (Default 01.5 )

Did not try it yet.

Yeah, Oliver 159.If that's a threaded chuck be careful running in reverse especially with a big old chunk of wood hanging out there! It can unscrew, same goes for stopping real fast. (Maybe you are not running in reverse but it looks like it is in the video.) Is that an Oliver, maybe 159?

Yes, I was running in reverse.

Yes, I know I need to be careful in reverse. My Logan is screw on chucks too.

I have not tried it yet, They say it is sometimes nice to sand in reverse, or maybe forward, then reverse, then forward, then reverse, etc.

I actually do have a set screw on the chuck, I have to see where it lands though. I don't want to mess up the spindle. Maybe a brass tipped set screw?