- Joined

- Jul 28, 2017

- Messages

- 2,376

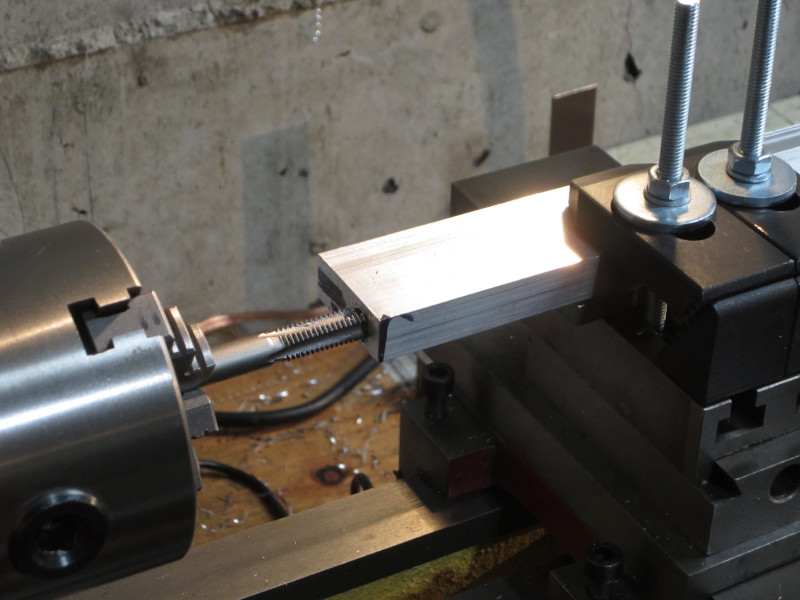

I recently had a project where I needed to drill and tap an 8mm hole on the end of a 7 inch long aluminum bar. It was too long to do it with my benchtop mill -- just not enough Z to do it once the chuck is installed. I started thinking about making a T-slot type replacement for the compound slide on my mini lathe, but then found that the hard work had already been done -- Little Machine Shop sells a replacement that has the necessary T slots. And the cost was reasonable, about $36. I didn't think I could MAKE something for a comparable price.

So I ordered it and it worked out very nicely for this particular job. I think it will come in handy for a number of things. Line boring comes to mind but I'm sure there will be other uses for it. It wasn't necessary to install the feed screw, I just tightened down the gib screws to hold it securely. Some spacers under the piece and the cross slide (and a machinist's square) were all I needed to get the proper alignment. As a bonus, peck drilling the hole was a piece of cake.

Here's a photo showing it in use. The attachment uses 8mm tee nuts with 6mm screw holes. The tee nuts came with the chuck for my rotary table and I used some 6mm all-thread for clamping the work. The clamps are from my mill's workholding kit. My lathe didn't like driving the tap so after starting the threads I moved the part to my vise and finished with a tap wrench.

So I ordered it and it worked out very nicely for this particular job. I think it will come in handy for a number of things. Line boring comes to mind but I'm sure there will be other uses for it. It wasn't necessary to install the feed screw, I just tightened down the gib screws to hold it securely. Some spacers under the piece and the cross slide (and a machinist's square) were all I needed to get the proper alignment. As a bonus, peck drilling the hole was a piece of cake.

Here's a photo showing it in use. The attachment uses 8mm tee nuts with 6mm screw holes. The tee nuts came with the chuck for my rotary table and I used some 6mm all-thread for clamping the work. The clamps are from my mill's workholding kit. My lathe didn't like driving the tap so after starting the threads I moved the part to my vise and finished with a tap wrench.