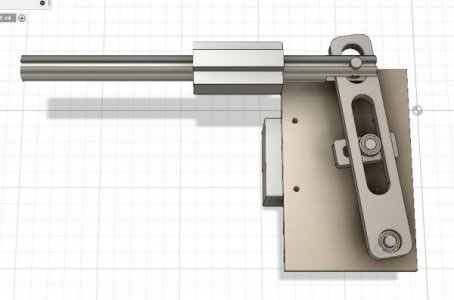

Here's a "working" concept of a small shaper. The design goal is for it to work in the lathe via a toolholder in the toolpost or, on a small table-top fixture. The main use will be for cutting fairly small keyways in pulleys or gear bores. I'm also using this project to learn Fusion 360 after many years of Alibre CAD.

The design is based on the classic Whitworth "Quick Return" slider/shaper mechanism. This is the first time I've used a CAD program for all the conceptual diagrams. I did not use a pencil or notepad for hand sketches like I usually do. I used pencil/paper only for a handful of trig problems and also to calculate the position, torque and speed of the slider rod given the small gear motor that was selected for the project.

This diagram is no-where near what it will finally look like. This diagram only shows the mechanical model to prove-out the basic design. My design goal was to have a shaper that had an adjustable stroke up to 3.25". Fusion 360 has stress analysis and simulation abilities and this conceptual model was used to verify the range of motion and stress areas. The computer model actually "works", in that the motor shaft can be turned and all members move accordingly. It was a fun little project to learn Fusion 360.

For reference, in this model, the slider rod is 8.5" long. The block that holds the slider is theoretically pinned in this model as is the motor and the plate that the assembly is mounted on.

The gear motor will be here in a couple weeks along with a fresh supply of small bearings. I'll work on the model until I'm happy with the "final" design and then I'll build it. Most of the components you see are in their final form but, the enclosure, clapper box and self adjusting mechanism is not even started yet. That will be pretty cut-and-dry.

I'll post a few more pictures at various milestones as things progress.

Ray

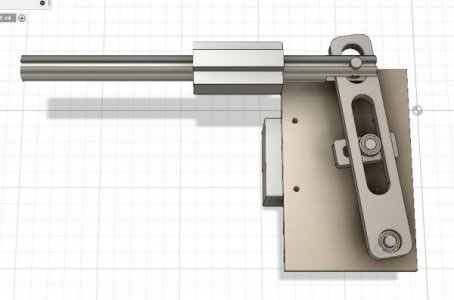

The design is based on the classic Whitworth "Quick Return" slider/shaper mechanism. This is the first time I've used a CAD program for all the conceptual diagrams. I did not use a pencil or notepad for hand sketches like I usually do. I used pencil/paper only for a handful of trig problems and also to calculate the position, torque and speed of the slider rod given the small gear motor that was selected for the project.

This diagram is no-where near what it will finally look like. This diagram only shows the mechanical model to prove-out the basic design. My design goal was to have a shaper that had an adjustable stroke up to 3.25". Fusion 360 has stress analysis and simulation abilities and this conceptual model was used to verify the range of motion and stress areas. The computer model actually "works", in that the motor shaft can be turned and all members move accordingly. It was a fun little project to learn Fusion 360.

For reference, in this model, the slider rod is 8.5" long. The block that holds the slider is theoretically pinned in this model as is the motor and the plate that the assembly is mounted on.

The gear motor will be here in a couple weeks along with a fresh supply of small bearings. I'll work on the model until I'm happy with the "final" design and then I'll build it. Most of the components you see are in their final form but, the enclosure, clapper box and self adjusting mechanism is not even started yet. That will be pretty cut-and-dry.

I'll post a few more pictures at various milestones as things progress.

Ray