- Joined

- Sep 29, 2017

- Messages

- 2,251

Hallo guys and girls

I have a question about these cheap

I understand that you need to place the magnet on the spindle or somewhere and place the sensor over the magnet,but my question is this. Say I place the magnet on the the driven step pulley,which have 4 pulleys which can be used, does it matter on which pulley you place it to achieve the correct rpm reading if my belts is set to reach 1300 max rpm at the moment? I am asking because we now the bigger the OD od the pulley,the faster that magnet is going to come past that sensor which will effect the rpm reading......right? I hope I explained it ok. I can't place the magnet directly on the spindle.

Thoughts please

Michael.

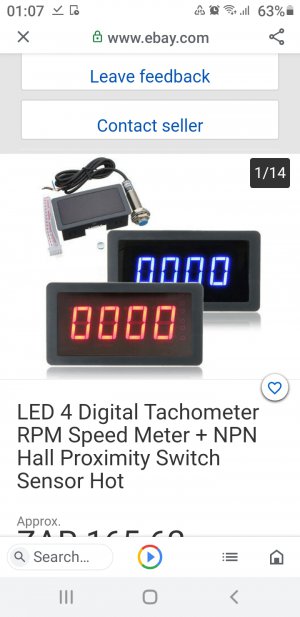

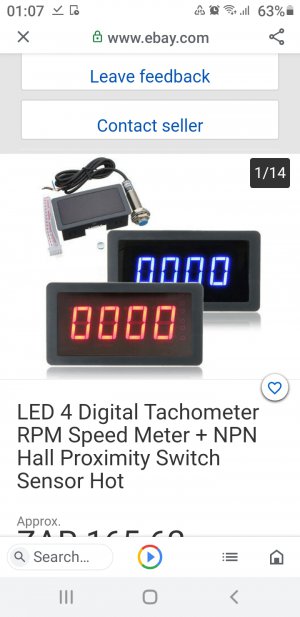

I have a question about these cheap

LED 4 Digital Tachometer RPM Speed Meter + NPN Hall Proximity Switch Sensor.

I understand that you need to place the magnet on the spindle or somewhere and place the sensor over the magnet,but my question is this. Say I place the magnet on the the driven step pulley,which have 4 pulleys which can be used, does it matter on which pulley you place it to achieve the correct rpm reading if my belts is set to reach 1300 max rpm at the moment? I am asking because we now the bigger the OD od the pulley,the faster that magnet is going to come past that sensor which will effect the rpm reading......right? I hope I explained it ok. I can't place the magnet directly on the spindle.

Thoughts please

Michael.

Had to swap out a blown motor last night with one of these mounted on it . Putting it all together was fine , lifting it and getting it back into the line was a nightmare as always .

Had to swap out a blown motor last night with one of these mounted on it . Putting it all together was fine , lifting it and getting it back into the line was a nightmare as always .