- Joined

- Sep 10, 2016

- Messages

- 8

Hi,

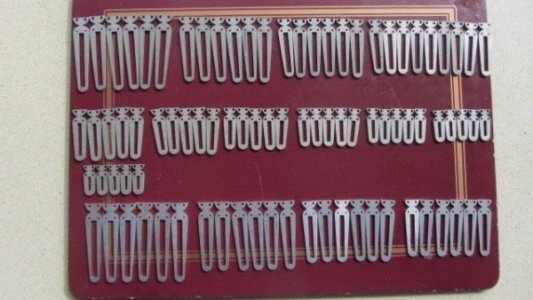

I have to tap 104 x 1.6mm threads through 52 pieces of Grade 2 Titanium. The pieces are 1.5mm thick and as yet have only pilot holes drilled through them., as they came from the makers.

Is it possible to tap these holes by hand and, if so what sort of tap should I use?

Any advice would be appreciated.

Thanks,

Mike

I have to tap 104 x 1.6mm threads through 52 pieces of Grade 2 Titanium. The pieces are 1.5mm thick and as yet have only pilot holes drilled through them., as they came from the makers.

Is it possible to tap these holes by hand and, if so what sort of tap should I use?

Any advice would be appreciated.

Thanks,

Mike