- Joined

- Dec 27, 2017

- Messages

- 340

Hi everyone,

I just got started with this little weekend business of mine. I am interested in selling a line of fixture plates and what I call "low-profile" clamps to go along with them. This got started because I told myself that I would make my own fixture plate about a year ago when I needed to machine something that the vice would not really help out with, and I just never got around to it . Then, the Corona hit and I was bored out of my mind and revisited my clamp idea for lack of anything better to do with my time.

. Then, the Corona hit and I was bored out of my mind and revisited my clamp idea for lack of anything better to do with my time.

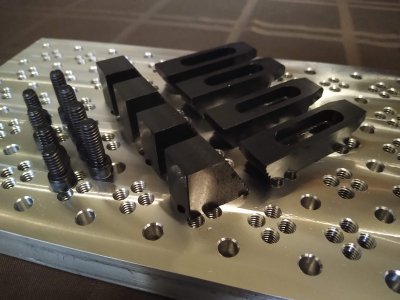

I produced the fixture plate and then the clamps came around a few days later. I wanted to make the clamps small so they can stay out of the way of the mill when a retract is called out and rapids are used. So, I made the clamps to allow the socket head cap screws to nestle inside.

Recently, I had an opportunity to make a little bit of income with some farm-out work from a local manufacture and they wanted me to take their A36 flame cut stock down to size so their operators can easily zero off a known size and go with it. I knew that a couple of the pieces would not be ideal for just clamping directly with the vice and I would need to make soft jaws to do it properly. Instead, I poped my fixture plate onto my vice and just used the clamps to hold the part down while I used a contour op to go around the sides of the part. If I needed the clamps to be moved to another side, I simply removed the clamps and shifted them around, keeping in mind to keep one locked down at all times so the part did not shift on me. It worked out just great and I did not have to make any soft jaws.

Here are the particulars of the fixture plate and the clamps:

Here are some pictures of the product and also some things I machined with them. Pictured holding onto the plate is a Kurt 4" vice.

My website is www.daytoncncproducts.com

I just got started with this little weekend business of mine. I am interested in selling a line of fixture plates and what I call "low-profile" clamps to go along with them. This got started because I told myself that I would make my own fixture plate about a year ago when I needed to machine something that the vice would not really help out with, and I just never got around to it

I produced the fixture plate and then the clamps came around a few days later. I wanted to make the clamps small so they can stay out of the way of the mill when a retract is called out and rapids are used. So, I made the clamps to allow the socket head cap screws to nestle inside.

Recently, I had an opportunity to make a little bit of income with some farm-out work from a local manufacture and they wanted me to take their A36 flame cut stock down to size so their operators can easily zero off a known size and go with it. I knew that a couple of the pieces would not be ideal for just clamping directly with the vice and I would need to make soft jaws to do it properly. Instead, I poped my fixture plate onto my vice and just used the clamps to hold the part down while I used a contour op to go around the sides of the part. If I needed the clamps to be moved to another side, I simply removed the clamps and shifted them around, keeping in mind to keep one locked down at all times so the part did not shift on me. It worked out just great and I did not have to make any soft jaws.

Here are the particulars of the fixture plate and the clamps:

- The plate measures 6" x 12" x 0.75" and are made out of aluminum

- 220, 1/4-20 threaded holes

- 72, 0.25" holes for dowel pins for 90 deg and 45 deg part location.

- Parts can be evenly spaced with the pins being used as a fence.

- The clamps measure 5/8" x 1/2" x 2.5" and are made out of 1018.

- When clamped down, they ride 0.25" above the part.

- recess to allow socket head cap screw to sit inside the clamp.

- No threaded stud for the end mill to strike against.

- serrated rear and matching step blocks.

Here are some pictures of the product and also some things I machined with them. Pictured holding onto the plate is a Kurt 4" vice.

My website is www.daytoncncproducts.com

Attachments

Last edited: