-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Giant Binocular

- Thread starter savarin

- Start date

- Joined

- Aug 22, 2012

- Messages

- 4,115

Have a read of this article

by having the mirror back curved to almost the same roc as the front should distort to an excellent parabola.

by having the mirror back curved to almost the same roc as the front should distort to an excellent parabola.

- Joined

- Sep 10, 2022

- Messages

- 928

Nice work. I have hand ground and polished 10 Dobsonian telescopes. Ranging in size from 4” to 17”. I really wished I had a machine to do the 17” and 12”. I have a 21” that I need to do one day. That will be a good retirement project.

I can’t wait to see you finish it. They will be awesome to view the sky.

Cutting oil is my blood.

I can’t wait to see you finish it. They will be awesome to view the sky.

Cutting oil is my blood.

- Joined

- Sep 10, 2022

- Messages

- 928

Here is a pic of us showing telescopes to the public. This was 15 years ago. My son with his back to us. That is a 7” un coated scope for viewing the moon. The larger blue scope is my 10-1/2” and the dude crossing his arms is me.

Cutting oil is my blood.

Cutting oil is my blood.

Very interesting, thanks!Have a read of this article

by having the mirror back curved to almost the same roc as the front should distort to an excellent parabola.

- Joined

- Aug 22, 2012

- Messages

- 4,115

Wow, 10 scopes, I am in awe, this is only my 4th and probably the last.Here is a pic of us showing telescopes to the public. This was 15 years ago. My son with his back to us. That is a 7” un coated scope for viewing the moon. The larger blue scope is my 10-1/2” and the dude crossing his arms is me.

I love sidewalk astronomy particularly when folks see the moon in close up and Saturn for the first time.

Its amazing how few people ever look up at the sky.

- Joined

- Sep 10, 2022

- Messages

- 928

Wow, 10 scopes, I am in awe, this is only my 4th and probably the last.

I love sidewalk astronomy particularly when folks see the moon in close up and Saturn for the first time.

Its amazing how few people ever look up at the sky.

It is amazing the number of people who have not seen the sky properly. So many people think it is fake when they see the planets or moon for the first time.

I actually had the pleasure of knowing John Dobson. He was a very interesting person. My telescope mentor had been friends with John from the late sixties making telescopes.

John Dobson (amateur astronomer) - Wikipedia

Cutting oil is my blood.

- Joined

- Feb 17, 2013

- Messages

- 4,406

Several year ago I built a telescope (including grinding the 10"mirror) under Dobson's tutelege. He certainly knew a HUGE AMOUNT about how to create a fantastic optical instrument for very little monetary outlay!

I later moved from Oregon to Arizona, and my 'scope survived the trip nicely. One of these days, I'll re-install the mirror, take it outside, and try some sky exploring.

PS - John Dobson and I share(d) a birthday.

I later moved from Oregon to Arizona, and my 'scope survived the trip nicely. One of these days, I'll re-install the mirror, take it outside, and try some sky exploring.

PS - John Dobson and I share(d) a birthday.

- Joined

- Sep 10, 2022

- Messages

- 928

Several year ago I built a telescope (including grinding the 10"mirror) under Dobson's tutelege. He certainly knew a HUGE AMOUNT about how to create a fantastic optical instrument for very little monetary outlay!

I later moved from Oregon to Arizona, and my 'scope survived the trip nicely. One of these days, I'll re-install the mirror, take it outside, and try some sky exploring.

PS - John Dobson and I share(d) a birthday.

So cool you got to learn from John. 10” mirrors are a bit time consuming but well worth the effort. They give great views and resolution.

Cutting oil is my blood.

- Joined

- Aug 22, 2012

- Messages

- 4,115

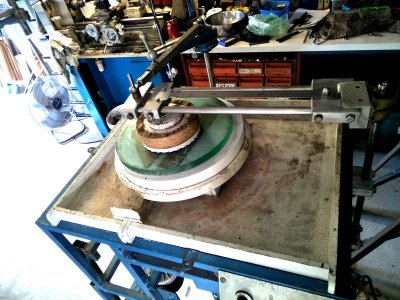

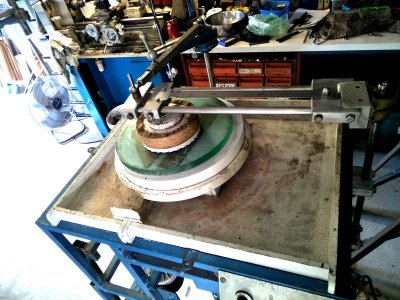

I thought you may be interested in the grinding / polishing machine.

Firstly the power pack, 2x toroidal transformers dropping the 240V 50Hz A/C down to 36V D/C, with 2 speed controllers.

The front control panel.

2 x 36V D/C motors. The square unit in the centre of the machine is the main turntable bearings, large dia taper rollers.

here you can see the speed reduction shafts and pulleys that drive the eccentric, this part pushes and pulls the laps across the mirror surface.

The overarm can be raised and lowered so it is always horizontal at 90 degrees to the turntable the same as the eccentric drive.

The eccentric drive pushes and pulls the overarm back and forth across the mirror depending upon the length of the stroke that can be set up.

The length of the eccentric arm can be adjusted in length and in the amount of movement.

All this work is very wet with abrasive grits so full coverage drip trays are necessary.

Just another overview.

The bar that the ruler is sitting on allows me to set repeat off sets and when the two little pointers are at zero the pin that sits in the tool holds it exactly on the centre of the turntable.

The same with the clamp that holds the eccentric scale, when set to zero there is no eccentric movement with a scale for repeat settings.

When grinding and polishing the tool spins from friction alone, its position on the glass will dictate the shape of the mirror surface. This is why the tool needs an off set adjustment and an amount of sweep adjustment.

The use of the two scales allows me to keep track of these variables. (assuming I remember to write them down in the diary)

Firstly the power pack, 2x toroidal transformers dropping the 240V 50Hz A/C down to 36V D/C, with 2 speed controllers.

The front control panel.

2 x 36V D/C motors. The square unit in the centre of the machine is the main turntable bearings, large dia taper rollers.

here you can see the speed reduction shafts and pulleys that drive the eccentric, this part pushes and pulls the laps across the mirror surface.

The overarm can be raised and lowered so it is always horizontal at 90 degrees to the turntable the same as the eccentric drive.

The eccentric drive pushes and pulls the overarm back and forth across the mirror depending upon the length of the stroke that can be set up.

The length of the eccentric arm can be adjusted in length and in the amount of movement.

All this work is very wet with abrasive grits so full coverage drip trays are necessary.

Just another overview.

The bar that the ruler is sitting on allows me to set repeat off sets and when the two little pointers are at zero the pin that sits in the tool holds it exactly on the centre of the turntable.

The same with the clamp that holds the eccentric scale, when set to zero there is no eccentric movement with a scale for repeat settings.

When grinding and polishing the tool spins from friction alone, its position on the glass will dictate the shape of the mirror surface. This is why the tool needs an off set adjustment and an amount of sweep adjustment.

The use of the two scales allows me to keep track of these variables. (assuming I remember to write them down in the diary)