- Joined

- Dec 24, 2020

- Messages

- 1,030

Part 1:

It all started with a text from a friend on a Tuesday afternoon: "There's a 24" G&E shaper in Fraser (40 miles away) on FB Marketplace for $500. Has a nice table and vise on it too". This from a friend who knows I have the space to take in a shaper, even though I have a lot of other projects lined up. Still, I pull up the listing, look at the pics and read the description. Yep, another homeless shaper, living under a tarp behind a building in an industrial area in the greater Detroit area. The tarp was developing holes, and the pallet for a bed was crumbling. Even the rope holding the tarp down against the wind and rain was frayed and starting to fail. So many of these cases are hopeless, with missing parts, terminal rust and hardware laying loose around them, but someone in the past had given this shaper a thick coat of Cosmoline on the bare metal and the many coats of paint had kept the worst at bay. Maybe, just maybe, there was a solid machine hidden under the flaking layers of paint, dried preservative, grit, dirt and grime.

I've wanted a shaper for a while, but wasn't in a hurry to add another major project to my long list of projects so I decided to sleep on it, and was somewhat hoping someone else would jump on it. Then I decided to sleep on it again. A couple of days passed and it was still there, then it showed up in one of the machinery buy/sell groups on FB. I saved the listing pictures, watched more than a couple of YouTube videos on shapers (some I'd already watched), looked at online manuals and probably had a couple of dreams about shapers those couple of nights. Still, I held off sending the seller a note.

At one point I was texting back and forth with the friend who sent the listing and one of us said something like "it's like buying a big vise with a shaper attached to it" and suddenly something clicked. Other than the trouble of getting it, I could scrap the machine, sell the vise and probably double my money at current prices so there was no way to lose. On the flip side, if it could be saved I'd have a shaper and not have to go terribly far to get it. At that point I sent the seller a note. We agreed I'd take a look at it over the weekend, and waited for Sunday since it was raining pretty much all day on Saturday. I didn't want to deal with loading/hauling in rain and they say to never buy a used car in the rain, so that's probably good advice for shapers as well.

I got to where the machine was on Sunday and it turns out I'd met the seller at an auction pickup a few months prior. I was picking up a Clausing 8520 and he was picking up a Seneca Falls lathe. We actually helped each other a bit while loading because the location was cramped. I said the shaper was behind an industrial building, and wow, there was a bunch of stuff back there with it! A large (probably over 10ft bed length) lathe and a Monarch 10EE were under tarps right next to the shaper, there was other stuff under tarps I couldn't identify, and all of it was backed up to a 1940s crane that gets used to move all this stuff! The crazy thing is the shop is owned by the seller's buddy and inside he had so much stuff you could barely move. I counted three lathes, four shapers, a planer, welders, horizontal mills, vertical mills, a couple of small tractors, mini forklifts, a Blanchard grinder and stuff on pallet racking to the ceiling...a fortune in cast iron for sure. Back to the shaper...

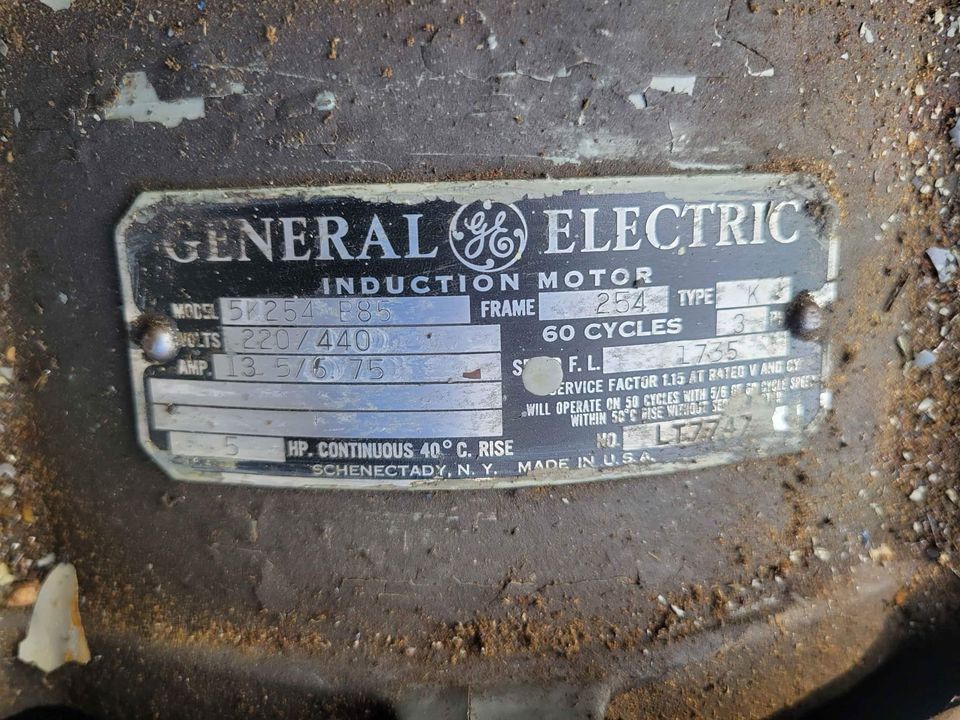

The shaper is a Gould & Eberhard 20-24" Industrial Universal model, serial number 2110A6, which puts it at the very beginning of 1940. Over on PM one of the posters said that serial number 2104A was the last one for 1939. I'm hoping that a break for the holidays had the G&E employees well rested and doing their best work on my shaper! The seller claimed he saw the machine run before he bought it and then ran out of shop room, so it never got moved indoors. It's missing the crank handles and the vise handle, but appears otherwise complete with no damage that's obvious. He had cleaned off a bit of the preservative to show the ways still had flaking showing. At that point I handed him some money, his buddy fired up the crane, we backed my trailer under it, set it down and I put straps on it to/from all four corners. As I was doing this the buddy who originally sent me the text showed up to take a look and got the inside shop tour as well.

I headed home, driving carefully and hoping I didn't have a 5,000lb boat anchor in the trailer behind me! I managed to get home and decided to leave the shaper in the trailer to save time and help catch the debris during the initial cleaning. I backed the trailer into my shop, unhooked my truck and breathed a huge sigh of relief! The first pics are the ones from the FB listing, and the last two are on the way home when I stopped for fuel. I had taken the motor pulley cover off because it only had one bolt holding it and it would have been flapping in the breeze on the highway.

To be continued...

It all started with a text from a friend on a Tuesday afternoon: "There's a 24" G&E shaper in Fraser (40 miles away) on FB Marketplace for $500. Has a nice table and vise on it too". This from a friend who knows I have the space to take in a shaper, even though I have a lot of other projects lined up. Still, I pull up the listing, look at the pics and read the description. Yep, another homeless shaper, living under a tarp behind a building in an industrial area in the greater Detroit area. The tarp was developing holes, and the pallet for a bed was crumbling. Even the rope holding the tarp down against the wind and rain was frayed and starting to fail. So many of these cases are hopeless, with missing parts, terminal rust and hardware laying loose around them, but someone in the past had given this shaper a thick coat of Cosmoline on the bare metal and the many coats of paint had kept the worst at bay. Maybe, just maybe, there was a solid machine hidden under the flaking layers of paint, dried preservative, grit, dirt and grime.

I've wanted a shaper for a while, but wasn't in a hurry to add another major project to my long list of projects so I decided to sleep on it, and was somewhat hoping someone else would jump on it. Then I decided to sleep on it again. A couple of days passed and it was still there, then it showed up in one of the machinery buy/sell groups on FB. I saved the listing pictures, watched more than a couple of YouTube videos on shapers (some I'd already watched), looked at online manuals and probably had a couple of dreams about shapers those couple of nights. Still, I held off sending the seller a note.

At one point I was texting back and forth with the friend who sent the listing and one of us said something like "it's like buying a big vise with a shaper attached to it" and suddenly something clicked. Other than the trouble of getting it, I could scrap the machine, sell the vise and probably double my money at current prices so there was no way to lose. On the flip side, if it could be saved I'd have a shaper and not have to go terribly far to get it. At that point I sent the seller a note. We agreed I'd take a look at it over the weekend, and waited for Sunday since it was raining pretty much all day on Saturday. I didn't want to deal with loading/hauling in rain and they say to never buy a used car in the rain, so that's probably good advice for shapers as well.

I got to where the machine was on Sunday and it turns out I'd met the seller at an auction pickup a few months prior. I was picking up a Clausing 8520 and he was picking up a Seneca Falls lathe. We actually helped each other a bit while loading because the location was cramped. I said the shaper was behind an industrial building, and wow, there was a bunch of stuff back there with it! A large (probably over 10ft bed length) lathe and a Monarch 10EE were under tarps right next to the shaper, there was other stuff under tarps I couldn't identify, and all of it was backed up to a 1940s crane that gets used to move all this stuff! The crazy thing is the shop is owned by the seller's buddy and inside he had so much stuff you could barely move. I counted three lathes, four shapers, a planer, welders, horizontal mills, vertical mills, a couple of small tractors, mini forklifts, a Blanchard grinder and stuff on pallet racking to the ceiling...a fortune in cast iron for sure. Back to the shaper...

The shaper is a Gould & Eberhard 20-24" Industrial Universal model, serial number 2110A6, which puts it at the very beginning of 1940. Over on PM one of the posters said that serial number 2104A was the last one for 1939. I'm hoping that a break for the holidays had the G&E employees well rested and doing their best work on my shaper! The seller claimed he saw the machine run before he bought it and then ran out of shop room, so it never got moved indoors. It's missing the crank handles and the vise handle, but appears otherwise complete with no damage that's obvious. He had cleaned off a bit of the preservative to show the ways still had flaking showing. At that point I handed him some money, his buddy fired up the crane, we backed my trailer under it, set it down and I put straps on it to/from all four corners. As I was doing this the buddy who originally sent me the text showed up to take a look and got the inside shop tour as well.

I headed home, driving carefully and hoping I didn't have a 5,000lb boat anchor in the trailer behind me! I managed to get home and decided to leave the shaper in the trailer to save time and help catch the debris during the initial cleaning. I backed the trailer into my shop, unhooked my truck and breathed a huge sigh of relief! The first pics are the ones from the FB listing, and the last two are on the way home when I stopped for fuel. I had taken the motor pulley cover off because it only had one bolt holding it and it would have been flapping in the breeze on the highway.

To be continued...