Do you remember the time when most of the things were made here, they were durable, repairable and they would last for a very long time?

Do you remember the time when shop and other hands-on trades training were part of the school curriculum?

And you also probably remember when all this deteriorated, was bought and moved oversees and centralized by mega corporations... And this is great for few industries, but for a lot of small shop and inventors, makers and hobbyists, there is a real need in local distributed manufacturing. We are looking for your help to spread the word about our new initiative which we call "The Power of Small".

What is The Power of Smallᵀᴹ ?

• Small businesses doing big projects with low amounts of capital;

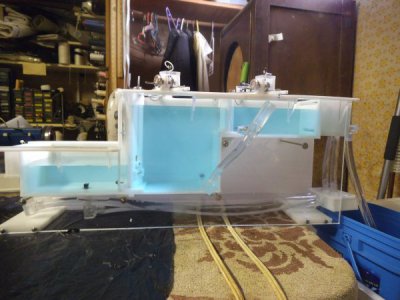

• Office-desk sized machines making large parts - 100lbs and more;

• On-shore, distributed manufacturing on a national or international scale;

• Converting 100% waste plastics directly into viable finished goods - affordably and locally;

• A sustainable and economical plastic molding and extrusion technology;

This isn't our fantasy. This is our reality.

Plastics have a reputation of being very harmful to the environment. While this may be true of plastics incorrectly disposed of, a lot of plastic can, and should, be recycled. The ability to convert previously used plastics into new products on a local scale isn't commercially viability. Yet.

We are actively working on a video series to explain how our new Omachron Plastics Inc. Molding and Extrusion Technology enables sustainable use of plastics.

You can check out our introductory clip here.

On our YouTube channel, you will also find another video series. Its purpose is to assist people with fabricating and machining plastics.

Our goal is to enable like-minded people to create a community dedicated to manufacturing high-quality plastic products cost-effectively, locally, and sustainably.

We are the most environmentally friendly company in this industry. Bold statement? Sure (literally and figuratively) - but why not subscribe to our channel and decide for yourself.

We encourage you to share your thoughts and recommendations with us. We're all in this together, and this is just the start!

Do you remember the time when shop and other hands-on trades training were part of the school curriculum?

And you also probably remember when all this deteriorated, was bought and moved oversees and centralized by mega corporations... And this is great for few industries, but for a lot of small shop and inventors, makers and hobbyists, there is a real need in local distributed manufacturing. We are looking for your help to spread the word about our new initiative which we call "The Power of Small".

What is The Power of Smallᵀᴹ ?

• Small businesses doing big projects with low amounts of capital;

• Office-desk sized machines making large parts - 100lbs and more;

• On-shore, distributed manufacturing on a national or international scale;

• Converting 100% waste plastics directly into viable finished goods - affordably and locally;

• A sustainable and economical plastic molding and extrusion technology;

This isn't our fantasy. This is our reality.

Plastics have a reputation of being very harmful to the environment. While this may be true of plastics incorrectly disposed of, a lot of plastic can, and should, be recycled. The ability to convert previously used plastics into new products on a local scale isn't commercially viability. Yet.

We are actively working on a video series to explain how our new Omachron Plastics Inc. Molding and Extrusion Technology enables sustainable use of plastics.

You can check out our introductory clip here.

On our YouTube channel, you will also find another video series. Its purpose is to assist people with fabricating and machining plastics.

Our goal is to enable like-minded people to create a community dedicated to manufacturing high-quality plastic products cost-effectively, locally, and sustainably.

We are the most environmentally friendly company in this industry. Bold statement? Sure (literally and figuratively) - but why not subscribe to our channel and decide for yourself.

We encourage you to share your thoughts and recommendations with us. We're all in this together, and this is just the start!

Last edited: