- Joined

- Jan 20, 2018

- Messages

- 5,623

View attachment The Retractor.mp4

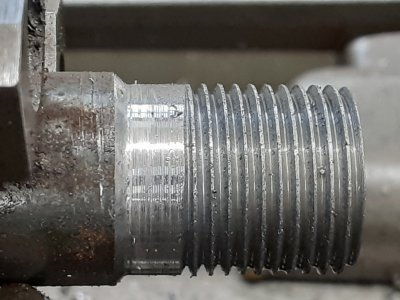

Some people (no one here) weren't satisfied with the automatic threading stop for my SB Heavy 10. They felt that the tool should also retract to avoid the necessity of a thread relief. I've always tried to fulfill people's unreasonable requests, so here goes. Please bear in mind that these things are designed on the fly, the unanticipated details and errors of one step influence the next.

Here's what we started with. The bearing is a guide bearing from a router bit.

I only needed one of these cams, but when I decided it needed another feature it was easier to just make another.

The additional feature on the cam was a .250 R. divot .005" deep at the high point, which provides a seat for the bearing when the tool is in the forward (working) position. Pushing the trip lever (bottom right of last picture) rotates the cam off center, then the pressure from the spring takes over, pushing the tool back as the cam rotates to its low point. The tool retracts 1/8", which should be plenty for all but the coarsest threads. A larger cam and some clearancing would allow for more retraction if needed.

This whole job would have been a lot easier with a surface grinder, but you work with what you have. I spent way too much time lapping the tool shank to provide a precision slip fit in the carrier. I still have to make the trip stop, haven't quite decided how it will be attached to the lathe. Video will follow once I've worked out those details.

Some people (no one here) weren't satisfied with the automatic threading stop for my SB Heavy 10. They felt that the tool should also retract to avoid the necessity of a thread relief. I've always tried to fulfill people's unreasonable requests, so here goes. Please bear in mind that these things are designed on the fly, the unanticipated details and errors of one step influence the next.

Here's what we started with. The bearing is a guide bearing from a router bit.

I only needed one of these cams, but when I decided it needed another feature it was easier to just make another.

The additional feature on the cam was a .250 R. divot .005" deep at the high point, which provides a seat for the bearing when the tool is in the forward (working) position. Pushing the trip lever (bottom right of last picture) rotates the cam off center, then the pressure from the spring takes over, pushing the tool back as the cam rotates to its low point. The tool retracts 1/8", which should be plenty for all but the coarsest threads. A larger cam and some clearancing would allow for more retraction if needed.

This whole job would have been a lot easier with a surface grinder, but you work with what you have. I spent way too much time lapping the tool shank to provide a precision slip fit in the carrier. I still have to make the trip stop, haven't quite decided how it will be attached to the lathe. Video will follow once I've worked out those details.

Last edited: