I'm a very inexperienced welder, but a well practiced miser and over thinker. I spent about a year researching before buying a much more expensive than originally budgeted welder.

The only spec based drawbacks I came across when looking at multi-function machines is that nothing is free. If you were to buy a single function machine for the same price as a multi-process, the single function will be a better, and often significantly better machine for that one process.

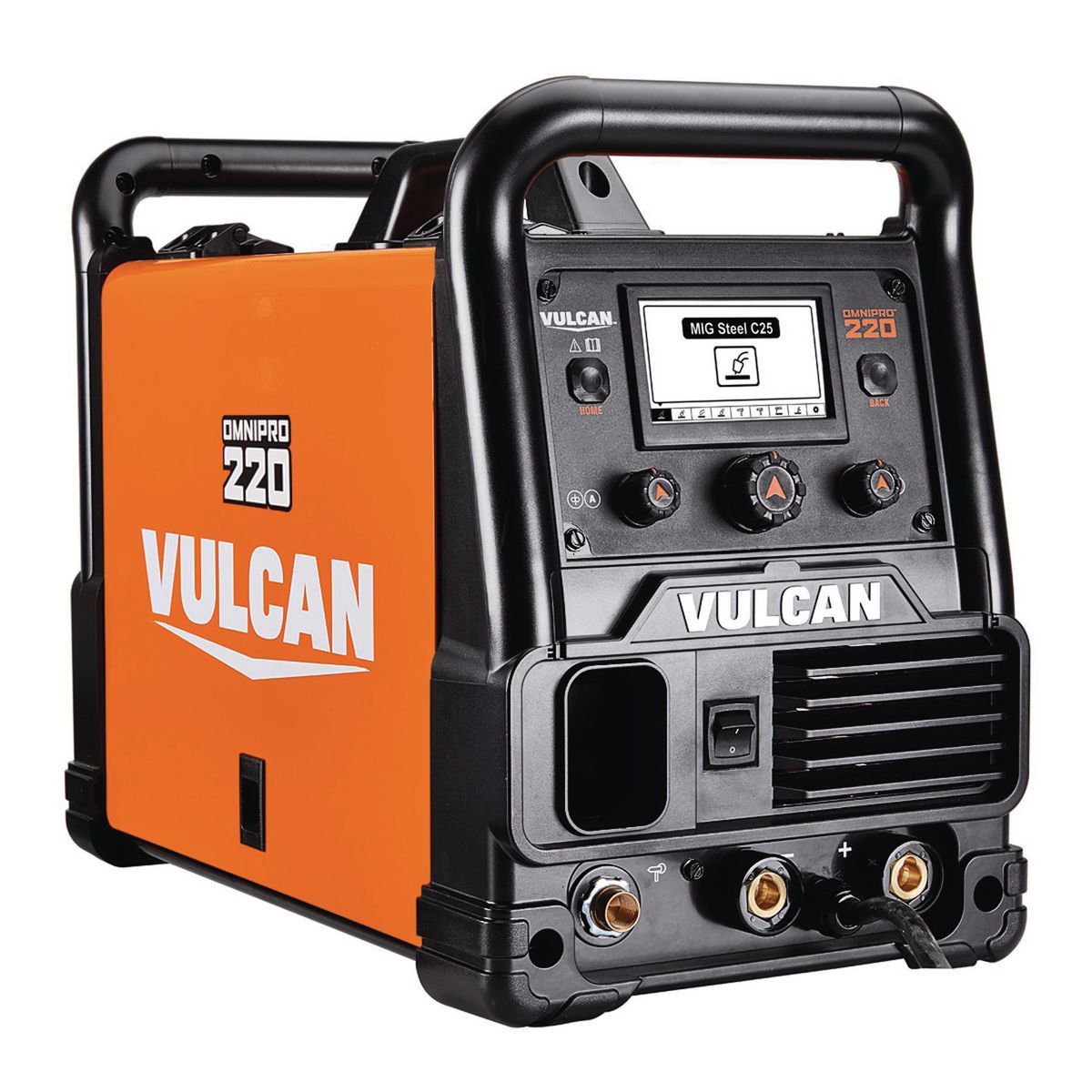

Also look closely at the details, the capabilities, and features not simply duty cycle and max power. How easily can you switch processes, switch polarity, change gasses etc. Some make this very easy, some literally require some disassembly of the machine. For stick welding look at the stick comparability, some work with almost everything, some are rather limited (most of the multi-process machines don't like 6010). The bigger names Miller, Lincoln, ESAB, make this info fairly easy to find and compare, some of the cheaper machines don't list things clearly making it hard to make a really good comparison.

The multi-process machines seem to be great for dabblers which applies to many of us hobbyists, but might come up a little short if you are mostly after one process and just thinking about the others as an after thought.