- Joined

- Dec 14, 2018

- Messages

- 629

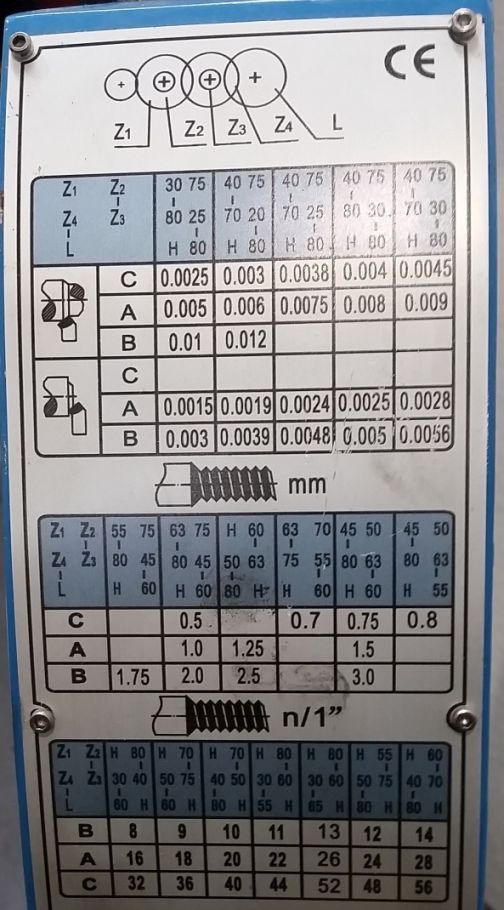

This is what's on the lathe itself. What's the top box for? If the middle is metric, the bottom box is inches, what's the top?

Also, when threading, should you use the slowest speed when turning?

www.hobby-machinist.com

www.hobby-machinist.com