-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Threading on a PM1127 lathe - turning instead of threading

- Thread starter Pcmaker

- Start date

- Joined

- Dec 20, 2012

- Messages

- 9,422

Your lathe will cut more threads than the typical QCGB lathe will. You just have to learn to use it properly.

Go buy the book, Gears and Gear Cutting for Home Machinists, by Ivan Law. It will educate you on how gear trains work and make it clearer how to work with your change gears.

Go buy the book, Gears and Gear Cutting for Home Machinists, by Ivan Law. It will educate you on how gear trains work and make it clearer how to work with your change gears.

- Joined

- Jun 12, 2018

- Messages

- 712

I think I got it to work, just need to tweak it a little bit. The gears are making more noise than it used to. I need to space them out with a piece of paper, like someone here recommended. I'm thinking of getting a .003 feeler gauge and cut it so it can fit between the gears and use that instead from now on.

- Joined

- Dec 20, 2012

- Messages

- 9,422

I'm thinking of getting a .003 feeler gauge and cut it so it can fit between the gears and use that instead from now on.

You cannot do this with a feeler gauge. The paper goes between the gear teeth of the two gears you are trying to mesh. It spaces the two gears by 0.003" so they fully engage but do not rub or bind against each other.

- Joined

- Dec 20, 2012

- Messages

- 9,422

Go buy the book, Gears and Gear Cutting for Home Machinists, by Ivan Law. It will educate you on how gear trains work and make it clearer how to work with your change gears.

Sorry, I meant to point you to a different book, Screw Cutting in the Lathe, by Martin Cleeve.

Last edited:

- Joined

- Aug 15, 2013

- Messages

- 2,114

Gears that are meshed too tightly together are noisy. Take a piece of heavy notebook paper or similar and squash it between gears as you mesh the gear teeth together. Then tighten the nuts/bolts/whatever secures the gears in place and rotate the gear train to feed the paper out. Watch this video from 4:20 to 4:55....... The gears are making more noise than it used to. I need to space them out with a piece of paper, like someone here recommended........

Tom

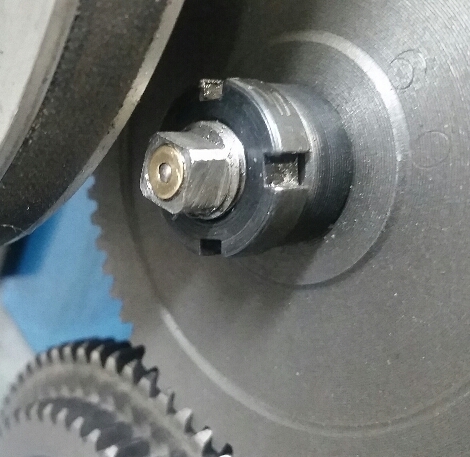

Those are to adjust the stack height, once set you shouldn't need to mess with them. Removing and installing the gears is done with the square drive on the end of the axle. The lathe came with a T-handle driver for them.