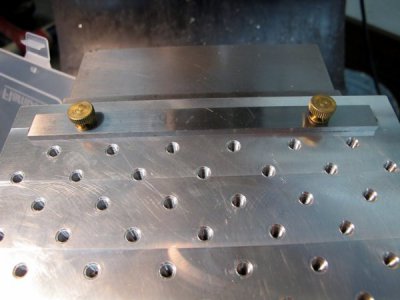

Thanks Ken, but that tilt table was built by Tom Lipton. I was merely showing the design I prefer. Bolting the entire round bar on the bottom/edge, allows the table to be re-ground or fly cut when it gets dinged up from use. I see this table as semi-sacrificial. You can cut and drill into it and not worry. Notch the round stock puts the table flush and thus, cannot be re-cut without hitting the bar. I would cut, face and turn the round bar and bolt to the bottom of the flat plate. Re-usable and an accurate pivot point. long set screws up front, to level on the vise top, and or you can use jack screws or whatever. 6" x 6", with 10-32 tapped holes. Very cool.