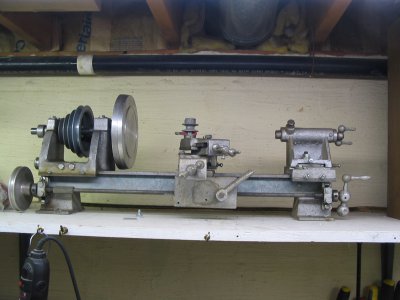

Hi, I've been thinking of making a different tool post for my gingery lathe, the one I use now is the lantern type, ( i think thats what its called,) round bar with slot with bolt in top center and spacers to put at the bottom to adjust height.

There must be something else simple to make that wont take so much screwing around to get it centered.

I have looked at alot but not sure if some of them will work as I have only .375" from top of compound rest to center of tail stock..

Any ideas or plans will be really appreciated,

Thanks,

Tim

There must be something else simple to make that wont take so much screwing around to get it centered.

I have looked at alot but not sure if some of them will work as I have only .375" from top of compound rest to center of tail stock..

Any ideas or plans will be really appreciated,

Thanks,

Tim

Now its Time for breakfast...

Now its Time for breakfast...