The centipede is far easier to store than a sheet of plywood and a couple saw horses. If I did it that way, the extra sheet would need to stay in the garage since I don’t want to walk up and down the basement stairs with a full sheet of plywood, as I get older, that is becoming more difficult. The foam board though is light enough that I can toss that on top of my mower and keep it put of the way.Or, just put a spare sheet of plywood on a couple of sawhorses, with foam board atop it.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Track saw vs tablesaw

- Thread starter jwmay

- Start date

- Joined

- Oct 13, 2014

- Messages

- 6,973

If only one, a Table saw, absolutely. I have owned table saws 45 years and a track saws about 25 years, I custom cabinetmaker for 20+ years. The Track saw does have its place but not even remotely as capable as a Table saw, overall.

If you're thinking that a track saw will be useful, it will likely be even more useful than you think. The safety aspect of a track saw is worth it on its own. They also have an amazing resale value, but you won't want to get rid of it. I have a Makita 36v and love it. I use my table saw a lot less frequently now.

- Joined

- Dec 15, 2018

- Messages

- 787

I've been thinking about getting one, even contemplated building one with linear bearings. In the end I bought a Makita corded one, just arrived this week. I've only made a couple of test cuts on some scrap Birch plywood but Im totally impressed. It has a scoring setting that just skims the top surface before making the cut. Virtually zero tear out.

Greg

Greg

- Joined

- Dec 21, 2018

- Messages

- 1,819

I'm a long time woodworker, professionally. I've owned a lot of saws over many years. A radial arm was my first one. I still had a DeWalt model GE 14" when I sold out. A radial arm saw would be the last type of saw I would buy. Consider instead a Makita compound miter saw with as large a blade size as you think you will need. Safer, more accurate, quicker to change angles on & on. If you are going to use a miter saw for production work, consider an Omga. Fine quality cuts after 100,000s of thousands. Quality blades are worth their price but you won't find them at places like Home Depot! Our best saw was a Schelling. Be safe.Funny enough, I’ve been considering a radial arm saw. Sometimes I think I like reading about tools more than using them. Lol

- Joined

- Nov 25, 2015

- Messages

- 8,370

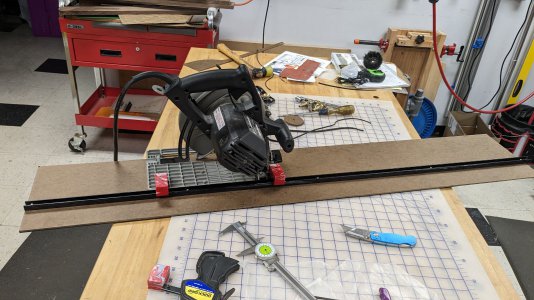

plans... plans... I got no stinkin plans... This is what I made for my son. He has a Makita saw, so this was with my left handed Porter Cable sidewinder for picture purposes.Would like to see someone's plans for a track saw . I have all the components on hand and just getting into the woodworking tools .

It's tempered hard board with an aluminum standard and drawer tool liner. I made some hdpe to follow the track.. and once mounted on his saw you cut through the hardboard to get a zero clearance guide. it works well even without clamps.

edit: Oh that little nub of shelf standard hanging out the end serves the purpose of providing a hanger hole to hang it on the wall, and to help align the saw while entering the cut.

Last edited:

- Joined

- Apr 14, 2014

- Messages

- 3,182

I've heard this a lot over the years. I've never used a radial arm saw in a professional capacity but have built a few houses and a number of decks and pieces of furniture using one. In many cases I prefer it to a table saw.I'm a long time woodworker, professionally. I've owned a lot of saws over many years. A radial arm was my first one. I still had a DeWalt model GE 14" when I sold out. A radial arm saw would be the last type of saw I would buy. Consider instead a Makita compound miter saw with as large a blade size as you think you will need. Safer, more accurate, quicker to change angles on & on. If you are going to use a miter saw for production work, consider an Omga. Fine quality cuts after 100,000s of thousands. Quality blades are worth their price but you won't find them at places like Home Depot! Our best saw was a Schelling. Be safe.

That being said there seems to be quite a number of both hobbyists and professionals that dislike this style saw. I can understand the hobbyists not liking them because of the learning curve and differences between professional grade and a hobbyist grade machines. It surprises me a bit that there are so many professionals that dislike them. I've yet to get specific answers as to why they have fallen so far out of favor. I seem to get generalities like "they aren't safe", "they're hard to control", or "they take up too much room and are cumbersome to use". To me they're just like any other industrial quality machine. You have to take the time to learn how to use them, recognize when they need blade changes and maintenance, and religiously follow safety precautions.

Maybe someone here can enlighten me to the specific reasons they personally dislike this type of saw.

- Joined

- Dec 21, 2018

- Messages

- 1,819

I can understand that. Cross cutting on a table saw is a pain for any decent length. A lot depends on what you have available and what needs to be accomplished. Trailer mounted radial arms used to be common on construction sites but haven't seen one in a long time. Sears was famous for selling them as the saw that could do almost anything. They sort of can but few of them as well as other methods. Too many people use the wrong blade on a RA making them self feed or grab.In many cases I prefer it to a table saw.

In my shop the RA was used to roughly cut planks to length or cut rips to fit the dumpster. We had and upcut, 18" 10hp saw for rapid cut to length. Scarry fast.

If you've got the space a sliding table saw can do most things well. Ours was a 16" SCMI that survived all sorts of miss use.