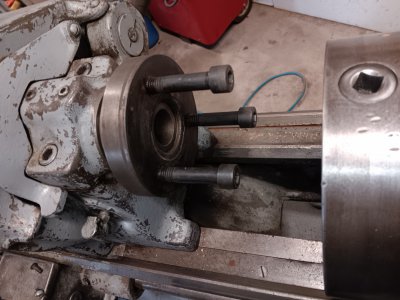

I have had this lathe for about 20 years, and have used it off and on over the years, but it has been a while since I used it. I am wanting to get back into machining again, and am looking into getting some accessories for the lathe. It came with a 4-jaw chuck, and I don't remember ever removing it, but am almost certain that it is threaded on. The Catalog number is CL187Y and serial number 9607RKL12-. It has a 3' bed and has the number 10 cast into the bed. The first thing I am wanting to find is a 3-jaw scroll chuck. I am thinking that the thread might be a 1-1/2-8, but can not confirm this. Since I have never removed the chuck, I have not measured the thread. I have not seen any information that can tell me what the thread should be for this lathe.

Which brings up another question; what is the proper way to remove the chuck. I do not want to damage anything in the process.

Can anyone tell me more about this little gem? Such as year of manufacture? Or anything else I should know. Can I get a collet chuck for it? Etc. I know I do not know much about it, but am working on that.

Thanks in advance,

Chris

Which brings up another question; what is the proper way to remove the chuck. I do not want to damage anything in the process.

Can anyone tell me more about this little gem? Such as year of manufacture? Or anything else I should know. Can I get a collet chuck for it? Etc. I know I do not know much about it, but am working on that.

Thanks in advance,

Chris