-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ultimate 3 phase converter

- Thread starter Karl_T

- Start date

- Joined

- Oct 14, 2014

- Messages

- 1,975

Just had a talk with the kid...

So many have called in sick where he works that they shut down all but one production line. He says he's most likely a Corona carrier right now. As my wife is high risk for serious illness, we decided I should not come over.

We will do it long distance. So, this project may take quite a while.

Karl

So many have called in sick where he works that they shut down all but one production line. He says he's most likely a Corona carrier right now. As my wife is high risk for serious illness, we decided I should not come over.

We will do it long distance. So, this project may take quite a while.

Karl

- Joined

- Oct 14, 2014

- Messages

- 1,975

OK, I am pretty experienced at wiring, but self taught. I put in a wire and test logic, then do another yada yada. When its wrong I fix as I go. I am not able to just sit down and write up an electrical diagram.

My son has almost no electrical logic experience. I have just done it for him.

So, I am breaking the logic wiring into baby steps. Below is my letter to him on getting the start caps working with a timer relay and a small contactor. See any problems?

------------------------------------------------------------------------------------------------------------

OK, you got two timer relays and one standard relay.

Both timers have the coil on pins 2 and 7.

Both timers have an NO contact from Pins 1 to pin 3

Lets build your logic one step at a time.

white wire on pin 7 to your common block.

"TEST" wire on pin 2 to someplace you can touch or switch 120 VAC. This will go to the standard relay later.

Another, very short, wire from pin1 to pin2 - hot wire for NO contact.

run a wire from pin3 to the coil on your start relay contactor.

run a white wire to the other side of the coil on the start relay contactor to your common terminal block.

Now test this assembly - touch test wire to 120VAC. Relay should energise after time delay and close start relay contactor.

Get this right and we will do next step.

Up to you but i would number each wire and make up a spreadsheet of where it is connected on each end and its function. then, in 20 years, you can quickly see what this does for quick repairs.

Dad

My son has almost no electrical logic experience. I have just done it for him.

So, I am breaking the logic wiring into baby steps. Below is my letter to him on getting the start caps working with a timer relay and a small contactor. See any problems?

------------------------------------------------------------------------------------------------------------

OK, you got two timer relays and one standard relay.

Both timers have the coil on pins 2 and 7.

Both timers have an NO contact from Pins 1 to pin 3

Lets build your logic one step at a time.

white wire on pin 7 to your common block.

"TEST" wire on pin 2 to someplace you can touch or switch 120 VAC. This will go to the standard relay later.

Another, very short, wire from pin1 to pin2 - hot wire for NO contact.

run a wire from pin3 to the coil on your start relay contactor.

run a white wire to the other side of the coil on the start relay contactor to your common terminal block.

Now test this assembly - touch test wire to 120VAC. Relay should energise after time delay and close start relay contactor.

Get this right and we will do next step.

Up to you but i would number each wire and make up a spreadsheet of where it is connected on each end and its function. then, in 20 years, you can quickly see what this does for quick repairs.

Dad

- Joined

- Oct 14, 2014

- Messages

- 1,975

OK here is letter 2 on getting a RED stop pushbutton and a GREEN go pushbtton to work with the standard coil in the previous post pic. Anybody see a problem here???

-----------------------------------------------------------------------------------------------------------------

when ready set up and test start stop push buttons.

1. "TEST" wire from one contact on RED button to switched 120 VAC - will go to L1 on your motor 1 contactor when all done.

2. wire from other contact on RED button to NO contact1 on GREEN button.

3. wire from NO contact1 on GREEN button to pin1 ?? on relay

4. wire from NO contact2 on GREEN button to coil on relay - should be pin2 ??

5. white wire from relay coil common pin7 ?? to common terminal block.

Now test assembly. With red button out, push green button - coil should close.

release button - coil should open.

Push in red button - green button should no longer work.

Now lets make that coil self latching. Run very short wire from NO contact on relay pin3 ?? to hot wire on its coil pin2 ??

Now re test => push green button and relay should stay on.

push red button and coil should drop.

-----------------------------------------------------------------------------------------------------------------

when ready set up and test start stop push buttons.

1. "TEST" wire from one contact on RED button to switched 120 VAC - will go to L1 on your motor 1 contactor when all done.

2. wire from other contact on RED button to NO contact1 on GREEN button.

3. wire from NO contact1 on GREEN button to pin1 ?? on relay

4. wire from NO contact2 on GREEN button to coil on relay - should be pin2 ??

5. white wire from relay coil common pin7 ?? to common terminal block.

Now test assembly. With red button out, push green button - coil should close.

release button - coil should open.

Push in red button - green button should no longer work.

Now lets make that coil self latching. Run very short wire from NO contact on relay pin3 ?? to hot wire on its coil pin2 ??

Now re test => push green button and relay should stay on.

push red button and coil should drop.

- Joined

- Feb 8, 2014

- Messages

- 11,144

Karl, that is painful for me to follow  But I think correct. It's interesting to see the differences in the way that people process logic problems. I would have to draw a ladder diagram to do it, I just process graphical information better than a narrative.

But I think correct. It's interesting to see the differences in the way that people process logic problems. I would have to draw a ladder diagram to do it, I just process graphical information better than a narrative.

You do realize that the Dayton time delay relay is an Interval On, thus pins 1-3 close on energize and open on timeout or when power is removed from the coil. Which is great for starting the motor in this case.

I don't know what the logic is on the ATC time delay relay.

But I think correct. It's interesting to see the differences in the way that people process logic problems. I would have to draw a ladder diagram to do it, I just process graphical information better than a narrative.

But I think correct. It's interesting to see the differences in the way that people process logic problems. I would have to draw a ladder diagram to do it, I just process graphical information better than a narrative.You do realize that the Dayton time delay relay is an Interval On, thus pins 1-3 close on energize and open on timeout or when power is removed from the coil. Which is great for starting the motor in this case.

I don't know what the logic is on the ATC time delay relay.

- Joined

- Oct 14, 2014

- Messages

- 1,975

Thanks Jim, appreciate the double check.

I do ladder logic with difficulty. I can read it, very hard to write it. No way can the kid work from that. he needs step by step - put this wire here. It was real hard for me to write it out this way. I "see" logic in my mind and have done some terribly complex stuff in <many> years past. I mostly used primitive computer programs for this. You know I still like Camsoft - mostly cause it is GREAT with logic. Galil is another good primitive programming language. Both better than machine language and assembler. I even did a lot of stuff with Fortran and even more with GM-Fanucs first attempt at a robot programming language. GOTO meant move to this point in 3D space.

I ASSUME all simple timer relays are powered on start then drop after timeout. I know you can buy complex multi function units. These are dumpster dive ones. if it don't work he may have to "BUY" one.

Karl

I do ladder logic with difficulty. I can read it, very hard to write it. No way can the kid work from that. he needs step by step - put this wire here. It was real hard for me to write it out this way. I "see" logic in my mind and have done some terribly complex stuff in <many> years past. I mostly used primitive computer programs for this. You know I still like Camsoft - mostly cause it is GREAT with logic. Galil is another good primitive programming language. Both better than machine language and assembler. I even did a lot of stuff with Fortran and even more with GM-Fanucs first attempt at a robot programming language. GOTO meant move to this point in 3D space.

I ASSUME all simple timer relays are powered on start then drop after timeout. I know you can buy complex multi function units. These are dumpster dive ones. if it don't work he may have to "BUY" one.

Karl

- Joined

- Feb 8, 2014

- Messages

- 11,144

I ASSUME all simple timer relays are powered on start then drop after timeout.

Not true at all. There is On Delay, Off Delay, Interval On, Recycle, and a couple others I don't remember right now. You have to look at the labeling. And in this case I think the Interval On or On Delay would work for this application.

- Joined

- Oct 14, 2014

- Messages

- 1,975

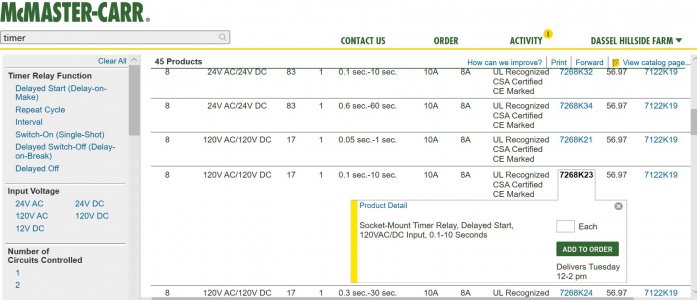

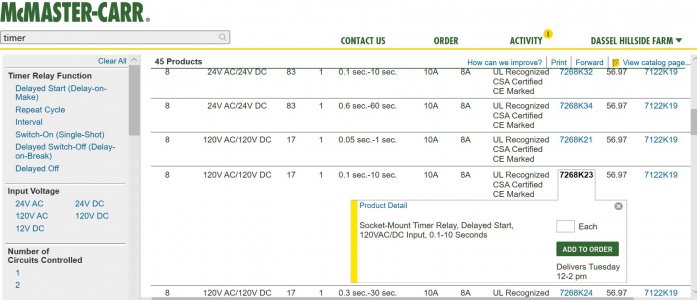

Ok, we got motor1 running and balanced with run caps. It sure took a LONG time on the phone to get a start stop self latching circuit working. had a couple basic mis-understandings.

The timer relay for motor2 is the standard delay on. While I know how to clobber this to work by taking the start-stop circuit power, we agreed he should get the correct relay. I won't be around in 20 years to help when it breaks down.

So, he's looking for a timer relay where the coil comes in after the set time. what's the correct name for this?

BTW, The kid stole a real nice CNC lathe at an auction last fall. He hooked it up yesterday for the first time. Everything came up and ran just fine - he can't do the spindle yet - needs motor2 running. See it here: https://www.hobby-machinist.com/threads/cnc-lathe.80345/

I am thinking this one, delayed start from mcmaster Carr:

The timer relay for motor2 is the standard delay on. While I know how to clobber this to work by taking the start-stop circuit power, we agreed he should get the correct relay. I won't be around in 20 years to help when it breaks down.

So, he's looking for a timer relay where the coil comes in after the set time. what's the correct name for this?

BTW, The kid stole a real nice CNC lathe at an auction last fall. He hooked it up yesterday for the first time. Everything came up and ran just fine - he can't do the spindle yet - needs motor2 running. See it here: https://www.hobby-machinist.com/threads/cnc-lathe.80345/

I am thinking this one, delayed start from mcmaster Carr:

Last edited: