- Joined

- Jun 12, 2014

- Messages

- 4,839

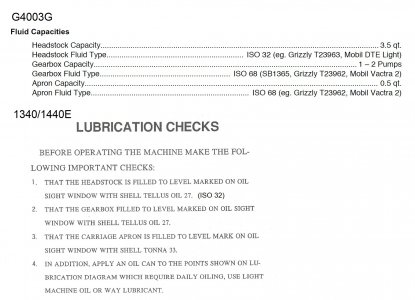

I think that was a smart decision to sell it. You may want to try the Amsoil marine gear drive oil, the diffidence in my gear head mill was significant over the stock oil, they just do not recommend synthetics during the break in on machines. Interesting in compressors that with stock mineral oil it is suppose to be changed every 200 hours, switching to synthetics it is around 2000 hours, so greatly increases the time interval. It is still good to change oils annually. Alternative would be something like Mobile heavy medium (ISO 68) gear oil, which is also what is specified for the lathe carriages and gearboxes. Most lathe recommend ISO 32 for the headstock, and that is one area where your comment about splash lubrication and flowing down to the bearings is important. In very hot environments some people use an ISO 46, but I always used ISO 32 in my PM-1340GT headstock and my current ERL-1340.