- Joined

- Nov 12, 2015

- Messages

- 497

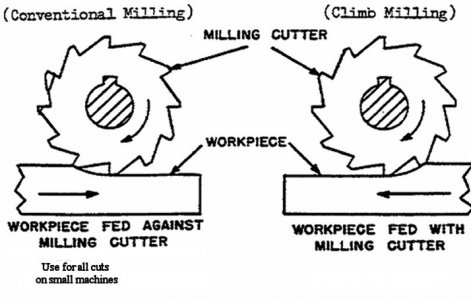

You always want your material to feed into the cutter, right side of the cutter 12 o'clock, clockwise, approaching the cutter from the 3 o'clock direction....clear as mud? It's material approach to the cutter direction, you want the open side of the cutter, the chip gullet, to engage the material first from whatever direction you are cranking.

Last edited: