- Joined

- Oct 26, 2023

- Messages

- 82

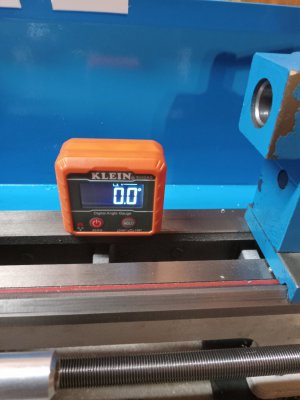

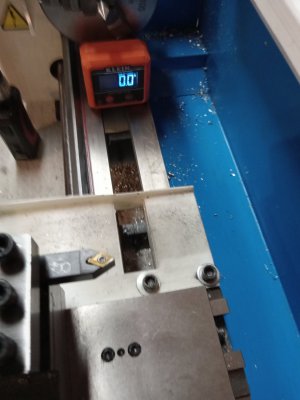

The tail stock and head stock on my lathe set on the ways at an angle and are not parallel to the bed.

Please see attached pictures. The lathe is performing great for my needs. The runout on the chuck is less then .0005 and the taper is .0005 over 6 inches supported and unsupported. My biggest concern is the footplate contact patch on the bed way is so small and narrow that it will wear the bed ways prematurely. What little I have used it you can see the discoloration line in the bed way. It looks like an easy fix but is it worth it?

Please see attached pictures. The lathe is performing great for my needs. The runout on the chuck is less then .0005 and the taper is .0005 over 6 inches supported and unsupported. My biggest concern is the footplate contact patch on the bed way is so small and narrow that it will wear the bed ways prematurely. What little I have used it you can see the discoloration line in the bed way. It looks like an easy fix but is it worth it?

Attachments

-

footplate contact.jpg134.2 KB · Views: 89

footplate contact.jpg134.2 KB · Views: 89 -

footplate angle.jpg182.2 KB · Views: 83

footplate angle.jpg182.2 KB · Views: 83 -

tailstock bed level.jpg178.2 KB · Views: 79

tailstock bed level.jpg178.2 KB · Views: 79 -

tail stock side level.jpg188.2 KB · Views: 67

tail stock side level.jpg188.2 KB · Views: 67 -

headstock side level.jpg232.8 KB · Views: 66

headstock side level.jpg232.8 KB · Views: 66 -

tailstock level.jpg163.7 KB · Views: 65

tailstock level.jpg163.7 KB · Views: 65 -

headstock end to end level.jpg205.1 KB · Views: 70

headstock end to end level.jpg205.1 KB · Views: 70 -

headstock bed level.jpg166.5 KB · Views: 79

headstock bed level.jpg166.5 KB · Views: 79