-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

War Time South Bend Lathe

- Thread starter Brain Coral

- Start date

- Joined

- Jul 26, 2013

- Messages

- 584

Well, I am finally back with a bit more done on the lathe. The parts came in from Maine with no damage and they will help immensely as I go along.

I was able to get the base completed, after making an adapter plate for the motor, and then making the v-belt adjusting mechanism from scratch, as the original was missing. I also had to press out the crankshaft from the crank bushing for the cone belt tension arm, as it was frozen solid. After pressing it out, I polished it in the lathe and put it back together with good results.

Then I reassembled the base, bed, legs and chip pan...

There is just a hint left of the original scraping on the ways....

I am thinking that this lathe sat out in the elements for quite some time, as everything I go to take apart is rusted together, and the ways are slightly pitted in places. Just trying to take the tail stock apart was a bear, with the side adjusting bolts frozen in place. It took nearly a week of heat and penetrating oil to finally take the two halves apart.

I decided to make two new adjustment bolts, as the old ones were very rusty and mashed up.

When I checked the pitch on the originals, I found that they were 5/8" x 12 tpi. I didn't have any all thread that size ( Isn't this an odd thread pitch for 5/8" ? ), so I decided to thread my own from some 3/4" ground rod. I didn't have anything to check the thread size as I went along, and there was no way to try the thread in the tail stock until I was done.

I haven't done much threading before, so I looked up the thread depth value in my Machinery's Handbook and used thread wires and a micrometer to get to the thread depth. Then I parted the two pieces, turned down one end each, and slotted them. After running a 12 tpi tap through the tail stock, I tried the bolts.... I was amazed that they fit perfectly, with no slop, but not tight. I guess that I got lucky

I found these .009" brass shims between the halves of the tail stock...

I now have the tailstock back together and on the lathe, with everything working nice and smooth.

I will tackle the headstock next.

Brian

I was able to get the base completed, after making an adapter plate for the motor, and then making the v-belt adjusting mechanism from scratch, as the original was missing. I also had to press out the crankshaft from the crank bushing for the cone belt tension arm, as it was frozen solid. After pressing it out, I polished it in the lathe and put it back together with good results.

Then I reassembled the base, bed, legs and chip pan...

There is just a hint left of the original scraping on the ways....

I am thinking that this lathe sat out in the elements for quite some time, as everything I go to take apart is rusted together, and the ways are slightly pitted in places. Just trying to take the tail stock apart was a bear, with the side adjusting bolts frozen in place. It took nearly a week of heat and penetrating oil to finally take the two halves apart.

I decided to make two new adjustment bolts, as the old ones were very rusty and mashed up.

When I checked the pitch on the originals, I found that they were 5/8" x 12 tpi. I didn't have any all thread that size ( Isn't this an odd thread pitch for 5/8" ? ), so I decided to thread my own from some 3/4" ground rod. I didn't have anything to check the thread size as I went along, and there was no way to try the thread in the tail stock until I was done.

I haven't done much threading before, so I looked up the thread depth value in my Machinery's Handbook and used thread wires and a micrometer to get to the thread depth. Then I parted the two pieces, turned down one end each, and slotted them. After running a 12 tpi tap through the tail stock, I tried the bolts.... I was amazed that they fit perfectly, with no slop, but not tight. I guess that I got lucky

I found these .009" brass shims between the halves of the tail stock...

I now have the tailstock back together and on the lathe, with everything working nice and smooth.

I will tackle the headstock next.

Brian

- Joined

- Jul 26, 2013

- Messages

- 584

Here's a couple of pics of the tailstock, back on the lathe and working nice and smoothly...

Here's the bare headstock, painted and back on the lathe...

At both the front and rear spindle bearings, the springed felt oilers were completely rotted away, with only pieces of broken spring present. The rear bearing looks pretty good...

The front bearing has some substantial scoring, but I will reassemble the headstock as is and see how the bearings run...

I am now, struggling with getting the cone pulley off of the spindle. It is frozen onto the spindle and does not spin on the spindle. Heat and penetrating oil will ensue....

Brian

Here's the bare headstock, painted and back on the lathe...

At both the front and rear spindle bearings, the springed felt oilers were completely rotted away, with only pieces of broken spring present. The rear bearing looks pretty good...

The front bearing has some substantial scoring, but I will reassemble the headstock as is and see how the bearings run...

I am now, struggling with getting the cone pulley off of the spindle. It is frozen onto the spindle and does not spin on the spindle. Heat and penetrating oil will ensue....

Brian

Last edited:

- Joined

- Jul 26, 2013

- Messages

- 584

This is an awesome project,a lathe with history and a whole lot of character and a good author to bring it back to life.

Hello Krol

Thanks..... it certainly is not on the order of what you are achieving with your South Bend. Your paint job looks fantastic !!!

Brian

- Joined

- Feb 2, 2013

- Messages

- 3,644

looking great Brian!

I couldn't tell from the pics, but one of the missing tags may have said "War Finish", this was a term for a lathe that was operable in all respects, but not a finely finished machine, we needed it for the war effort, no telling how much this contributed to winning the war---Just guessing the flame cutting may have been a way to speed up construction times.

Regardless, it is a fine machine, and your restoration work is beautiful.

olcopper

On edit: The hole on top of the tailstock opposite the lock down bolt is for a "dauber" and there are plans for building one on line----you may know, but, let's see if anyone else knows what was used in the old days as lubricant.

oc

Regardless, it is a fine machine, and your restoration work is beautiful.

olcopper

On edit: The hole on top of the tailstock opposite the lock down bolt is for a "dauber" and there are plans for building one on line----you may know, but, let's see if anyone else knows what was used in the old days as lubricant.

oc

Last edited:

- Joined

- Jul 26, 2013

- Messages

- 584

Hello OC,

Thank you for your kind words...

The flame cut compound is clearly a home built one, although fairly well executed. I have the replacement, waiting in the wings. In the mid 70's that particular lubricant, applied with the dauber, was still used in high school...

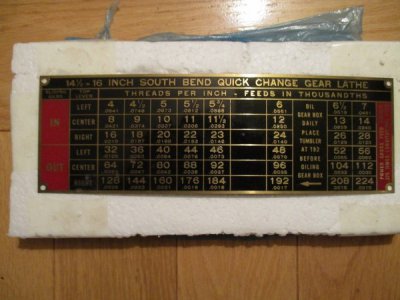

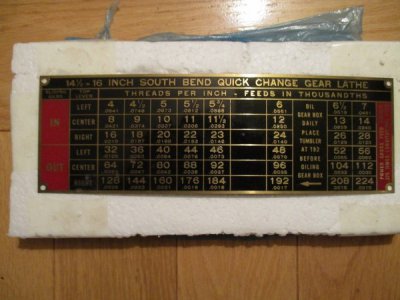

Here's a photo of a NOS chart that I got in the mail just the other day from a fellow from the U.S.A.

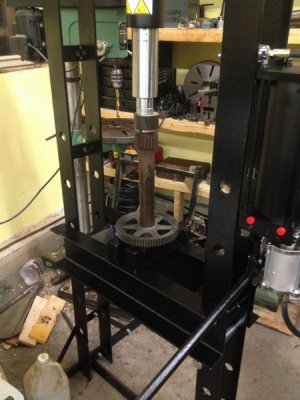

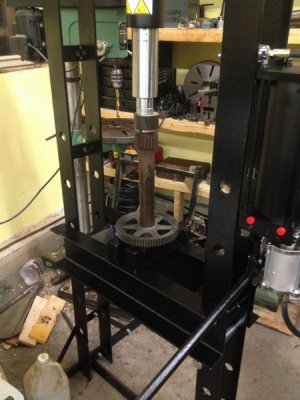

Here's a pic of me pressing on a new back gear from a fellow in Maine. Mine had a tooth missing....

Oops.... that's not the pic....

There we go...

Brian

Thank you for your kind words...

The flame cut compound is clearly a home built one, although fairly well executed. I have the replacement, waiting in the wings. In the mid 70's that particular lubricant, applied with the dauber, was still used in high school...

Here's a photo of a NOS chart that I got in the mail just the other day from a fellow from the U.S.A.

Here's a pic of me pressing on a new back gear from a fellow in Maine. Mine had a tooth missing....

Oops.... that's not the pic....

There we go...

Brian

Last edited:

I couldn't tell from the pics, but one of the missing tags may have said "War Finish", this was a term for a lathe that was operable in all respects, but not a finely finished machine, we needed it for the war effort, no telling how much this contributed to winning the war---Just guessing the flame cutting may have been a way to speed up construction times.

Regardless, it is a fine machine, and your restoration work is beautiful.

olcopper

On edit: The hole on top of the tailstock opposite the lock down bolt is for a "dauber" and there are plans for building one on line----you may know, but, let's see if anyone else knows what was used in the old days as lubricant.

oc

I believe it was white lead?

Sent from my iPhone using Tapatalk