- Joined

- Feb 9, 2017

- Messages

- 5,249

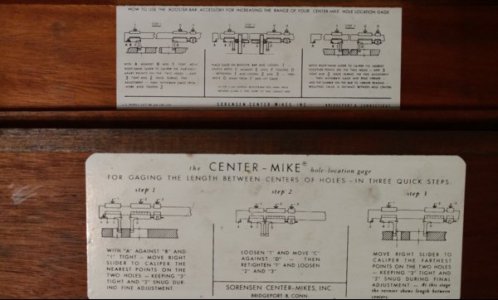

Emilio I'm no expert, but the calibration or practice gage that came with the 8" Mike is 4.9967". After some practice I could replicate to well within .001". The Mike is not calibrated for tenths so by looking at where I was between the .001's I could see I was within a couple of tenths. Like reading a micrometer it's all about feel and alignment. For me this is way easier than using a caliper mostly because of the rounded features on the ends of the Mike.

I'm not sure what you mean Brockwood about directly transferring, but the Mike is made to give you the measurement, not to mark with.

I'm not sure what you mean Brockwood about directly transferring, but the Mike is made to give you the measurement, not to mark with.