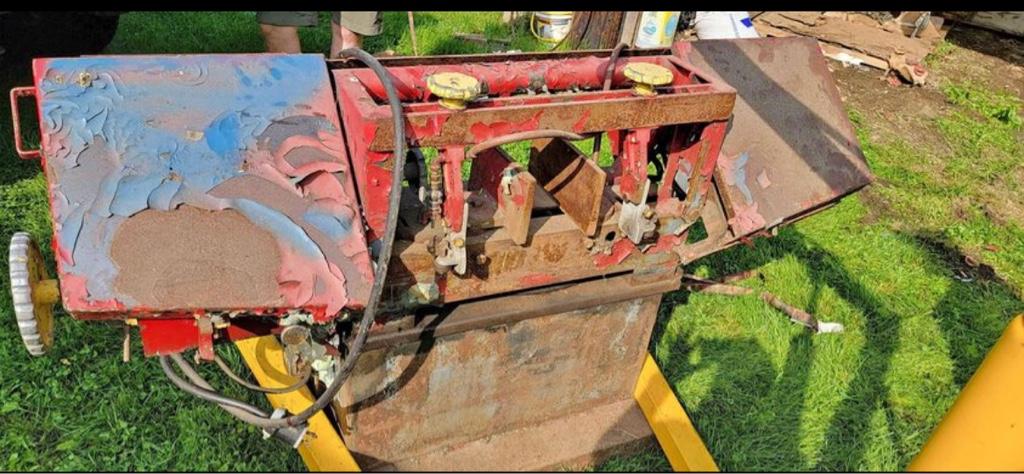

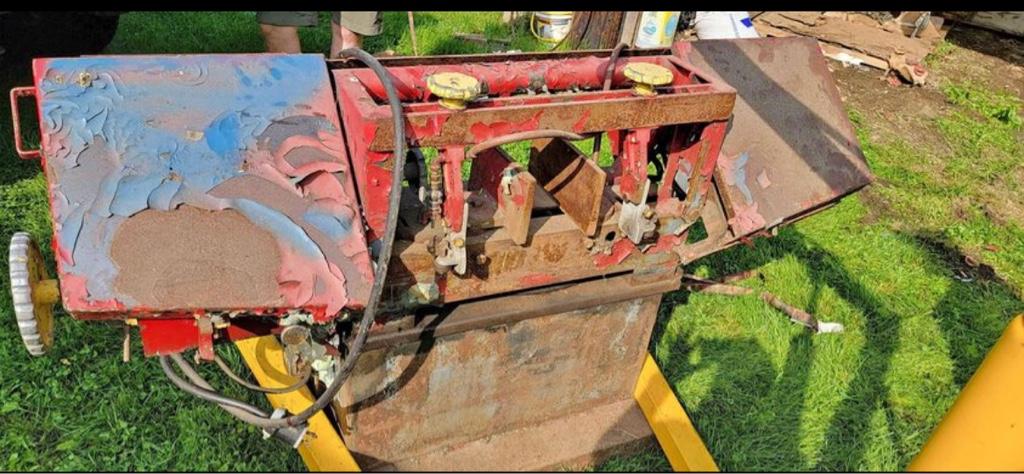

Hi. I just picked up a really nice shed find bandsaw. I believe it is a L-9 Wellsaw. Unsure of the model because the machine has no bling (badges etc.), and I can’t see any numbers of any kind except for a faint ghost image where the main badge used to be. The saw has survived surprisingly well, considering it’s curling three-colors of paint, and unknown history.

There were 2 different blade guide bearings missing, and another not missing that needed replacement. Fortunately, due to my hoarding tendencies, I happened to have the exact ones I needed tucked away in one of my miscellaneous drawers!! The motor functioning was a big question mark, but works fine on my home built phase converter. It really purrs. I’m very pleased this has the optional variable speed drive. The last thing I have to fix is the hydraulic drop limiter cylinder which has some NASTY old red rubber hose (maybe old radiator hose?). When I pull/push the rod, I can hear what sounds like a percolator brewing coffee, and no pressure can hold in the cylinder. I’m guessing that the gummy mess that was the hoses have given way, and succumbed to the ravages of time. My question is this: what would people recommend to replace these with? I doubt there is a great deal of pressure in this application. All in all, I am very happy with the marketplace find, and equally pleased with the $100 price for a $200 advertised saw.

Sent from my iPhone using Tapatalk

There were 2 different blade guide bearings missing, and another not missing that needed replacement. Fortunately, due to my hoarding tendencies, I happened to have the exact ones I needed tucked away in one of my miscellaneous drawers!! The motor functioning was a big question mark, but works fine on my home built phase converter. It really purrs. I’m very pleased this has the optional variable speed drive. The last thing I have to fix is the hydraulic drop limiter cylinder which has some NASTY old red rubber hose (maybe old radiator hose?). When I pull/push the rod, I can hear what sounds like a percolator brewing coffee, and no pressure can hold in the cylinder. I’m guessing that the gummy mess that was the hoses have given way, and succumbed to the ravages of time. My question is this: what would people recommend to replace these with? I doubt there is a great deal of pressure in this application. All in all, I am very happy with the marketplace find, and equally pleased with the $100 price for a $200 advertised saw.

Sent from my iPhone using Tapatalk