- Joined

- Apr 28, 2014

- Messages

- 3,590

I actually have a plastic shoe-box by the door with gauze, bandages, and a couple of hand towels so that if...I had an unfortunate incident recently. I completely forgot basic knife safety while opening some packaging and cut my thumb up really, really badly. This was bad, but I made it worse by panicking, running out of my shop where my first aid kit was, and accidently locked myself out. Thankfully, the cut wasn't bad enough to be dangerous, but what if?

I'm a very forgetful person, so I decided I needed to do something about it:

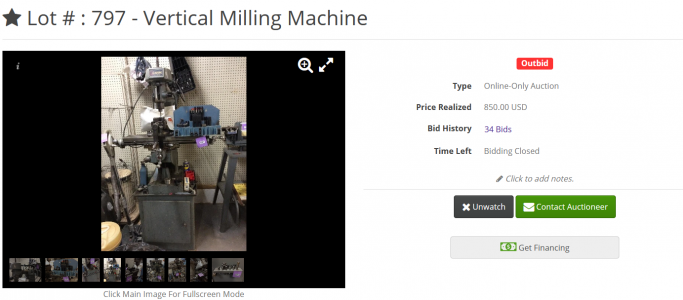

View attachment 359550

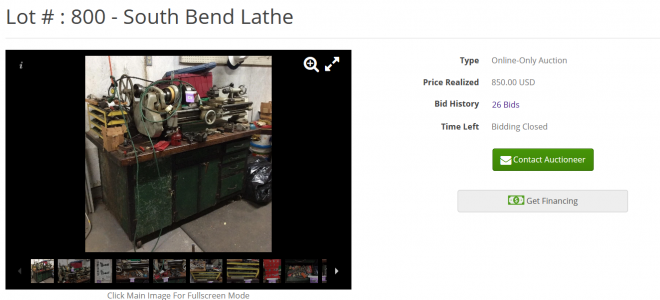

View attachment 359551

I bought a giant first aid kit that I can mount to the wall of my shop. It's super hard to miss, has everything I'd need to deal with the injuries I'm competent enough to deal with, and I can order refills when stuff expires.

Was this overkill? Yes. Was this overpriced? Also probably yes. Was it easier than making my own first aid kit? Absolutely. I'd rather spend the money for convenience and get the thing that could save my life right away.

(I'm also going to make it much harder to lock myself out of my shop.)

When I sliced my finger up on the box fan it worked as intended.