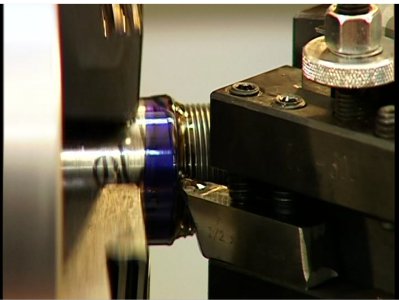

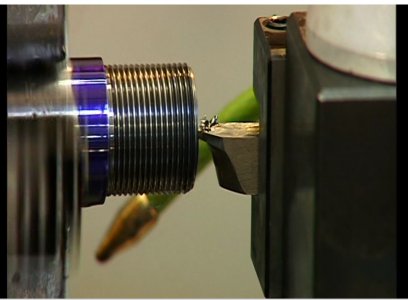

Can anyone help me figure out what insert this is? Seems like I can do a lot of different things with this insert that I can't do with my other inserts.

Or if there are better inserts than this. When I try to cut at a 25 degree the insert holder starts to rub on what I'm turning because the insert doesn't protrude far enough from the holder.

Thanks!!

Or if there are better inserts than this. When I try to cut at a 25 degree the insert holder starts to rub on what I'm turning because the insert doesn't protrude far enough from the holder.

Thanks!!