- Joined

- Aug 23, 2014

- Messages

- 932

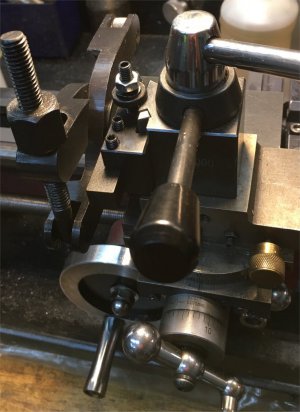

Here is one with a 5/16" holder for $29.95:

This one is $24.95:

I'm assuming you have a QCTP? you can use up to 1/2" holder with a 0XA QCTP. The original tool post on a minilathe is made for 5/16". I'm suggesting not buying the more expensive ones since you will most likely want to make your own when you have the equipment.

These should do what you want and give a decent knurl.

Roy

Spring Loaded Clamp Type Knurling Tool 2" Inches Capacity 5/16" Shank for Lathes - - Amazon.com

Spring Loaded Clamp Type Knurling Tool 2" Inches Capacity 5/16" Shank for Lathes - - Amazon.com

www.amazon.com

This one is $24.95:

2" Capacity Knurling Tool 5/16" - 8mm Shank to Hold in Quick Change Tool Post - - Amazon.com

2" Capacity Knurling Tool 5/16" - 8mm Shank to Hold in Quick Change Tool Post - - Amazon.com

www.amazon.com

I'm assuming you have a QCTP? you can use up to 1/2" holder with a 0XA QCTP. The original tool post on a minilathe is made for 5/16". I'm suggesting not buying the more expensive ones since you will most likely want to make your own when you have the equipment.

These should do what you want and give a decent knurl.

Roy