-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What sizers power belt for PM1340

- Thread starter chiroone

- Start date

- Joined

- Oct 27, 2016

- Messages

- 286

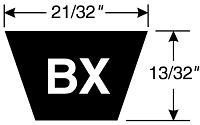

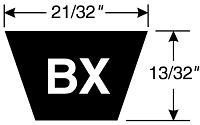

size BX24 and size BX25

I got mine from here.

www.biedlers-belts.com

www.biedlers-belts.com

David

I got mine from here.

Gates BX25 Belt

Tri-Power Notched Belt BX Section - Price: $10.68; Width: 5/8"; Length: 28"; SKU: 9013-2025

David

- Joined

- Jun 12, 2014

- Messages

- 4,810

Flip the motor pulley and run it as a single belt speed, it would take a Gates Tri-Power BX-26 belt. If one is using a non-VFD PM-1340GT and wants to retain a 2 speed pulley drive one needs a BX-24 and a BX25 belt, the stock belt is somewhere in between those two.

When running off of a VFD If you want quicker stops, set a higher mechanical RPM drive setting and turn down the VFD Hz. So for threading I usually run my VFD at around 20-30 Hz. There is less mechanical momentum in the drive system.

Using a VFD and flipping the motor pulley, use a BX-26 (If I recall a few people have also used a BX-27):

Stock non-VFD would need a BX-24 and BX-25:

When running off of a VFD If you want quicker stops, set a higher mechanical RPM drive setting and turn down the VFD Hz. So for threading I usually run my VFD at around 20-30 Hz. There is less mechanical momentum in the drive system.

Using a VFD and flipping the motor pulley, use a BX-26 (If I recall a few people have also used a BX-27):

Stock non-VFD would need a BX-24 and BX-25:

- Joined

- Oct 27, 2016

- Messages

- 286

I guess I'll flip the pulley and order a new BX26 belt, somehow every time I read one of Mark Jacobs or David Bests posts I learn something new.Flip the motor pulley and run it as a single belt speed, it would take a Gates Tri-Power BX-26 belt. If one is using a non-VFD PM-1340GT and wants to retain a 2 speed pulley drive one needs a BX-24 and a BX25 belt, the stock belt is somewhere in between those two.

When running off of a VFD If you want quicker stops, set a higher mechanical RPM drive setting and turn down the VFD Hz. So for threading I usually run my VFD at around 20-30 Hz. There is less mechanical momentum in the drive system.

Using a VFD and flipping the motor pulley, use a BX-26 (If I recall a few people have also used a BX-27):

View attachment 320663

Stock non-VFD would need a BX-24 and BX-25:

View attachment 320664

Thanks for the info.

David.

- Joined

- Jun 12, 2014

- Messages

- 4,810

No pulley changes for low and high speed. The stock large motor pulley to large headstock pulley splits the difference between the pulley ratios, so with a VFD running to 20-90/100 Hz should give you a spindle speed range of 50-2000 RPM using the gearbox ratios/VFD. When running an inverter style motor which goes to 120-125 Hz, using a ~2.3" pulley you get about the same speed range with more optimal motor performance in the constant Hp range.

- Joined

- Nov 23, 2020

- Messages

- 787

Mark,No pulley changes for low and high speed. The stock large motor pulley to large headstock pulley splits the difference between the pulley ratios, so with a VFD running to 20-90/100 Hz should give you a spindle speed range of 50-2000 RPM using the gearbox ratios/VFD. When running an inverter style motor which goes to 120-125 Hz, using a ~2.3" pulley you get about the same speed range with more optimal motor performance in the constant Hp range.

Do you have a thread that dives into this? I am trying to decide what direction to go with for my now on its way 1340GT 3 Phase.

Thanks!

- Joined

- Jan 26, 2021

- Messages

- 344

I learn that my wallet gets lighter after reading their posts.somehow every time I read one of Mark Jacobs or David Bests posts I learn something new.

- Joined

- Nov 23, 2020

- Messages

- 787

No truer words...I learn that my wallet gets lighter after reading their posts.

- Joined

- Dec 26, 2015

- Messages

- 2,079

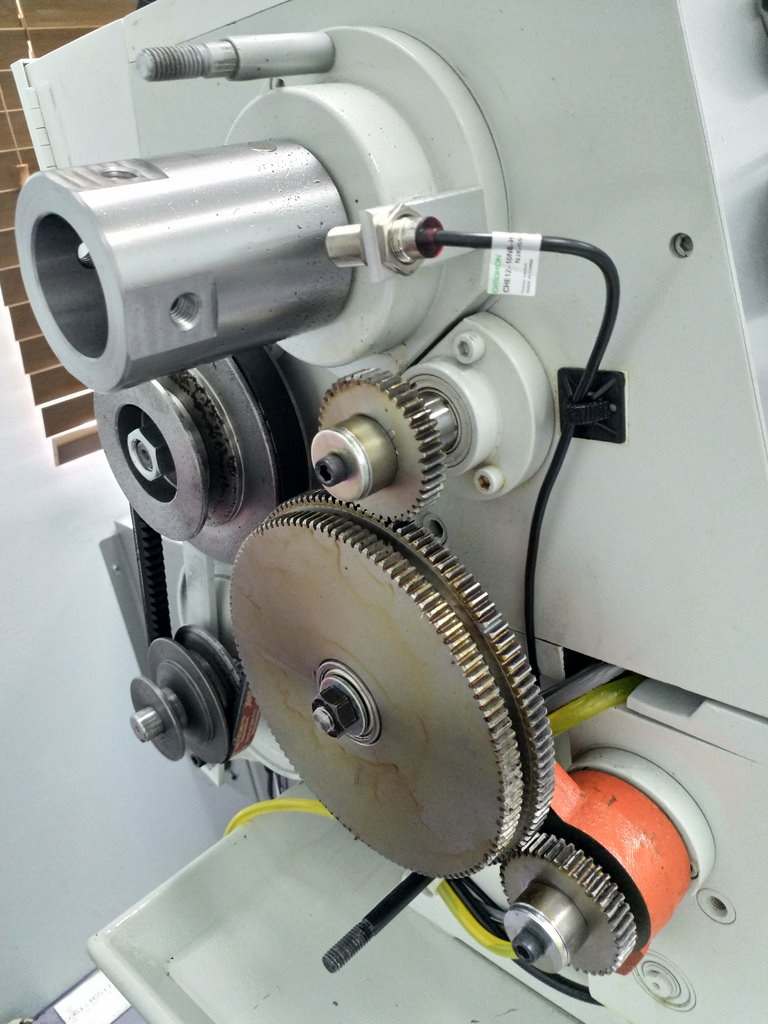

Perhaps this will help you - especially if you're considering a VFD configuration. I have posted speed tests of my PM-1340GT here using Mark's control package with Hitachi VFD. The first photo describes the motor/belt/pulley setup. The videos that follow illustrate the range of speeds available in Low/Low and High/High gear settings, along with the actual RPM with the VFD at 60Hz in each of the six possible gear settings. With this setup I am able to achieve 24 to 2081 RPM with a single belt position. And with the JOG function, I have sufficient torque to run a 5/8-11 tap (in a tailstock-mounted tap holder) into 304 stainless at 24 RPM using the Jog joystick for control (I haven't tried anything larger - yet).Mark,

Do you have a thread that dives into this? I am trying to decide what direction to go with for my now on its way 1340GT 3 Phase.

Thanks!