That sums it up very well.It does not take the place of a mill but its better than nothing and is definitely way cheaper.

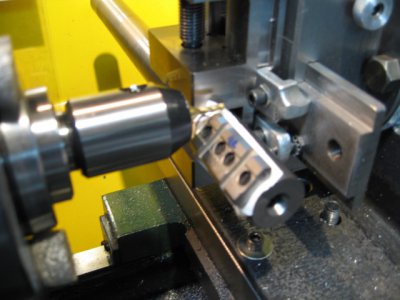

My milling attachment is completely homemade starting with a piece of angle iron.

It has worked out well for what I had to do. Will dig out some pictures.