- Joined

- Jul 2, 2018

- Messages

- 58

Good afternoon,

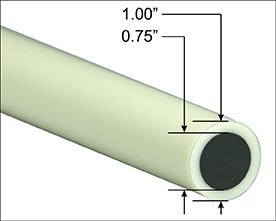

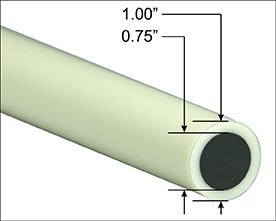

We now perfected a technique of molding this 2 colored rod in machine grade ABS, so now that we have it, what would you make out of it?

We have a 3 question form on our site to gather your ideas, or just respond to this thread.

It should be a fun brain teaser!

Thanks for participating!

We now perfected a technique of molding this 2 colored rod in machine grade ABS, so now that we have it, what would you make out of it?

We have a 3 question form on our site to gather your ideas, or just respond to this thread.

It should be a fun brain teaser!

Thanks for participating!