- Joined

- Jun 12, 2014

- Messages

- 4,817

No offense on the picture, I thought it was a bit of humor, but then I may not know what it relates too. We all start out at that level and then learn along the way.

To do a basic VFD install for this lathe will run around $600-700 inclusive of the VFD (WJ200-15SF), enclosure, braking resistor, power switch and wiring. Time to build out the VFD enclosure and program the VFD, figure 6-8 hours for the basics. It is straight forward wiring, but if one is not familiar with electrical wiring then takes longer and definitely have an electrician check everything before powering it up. It takes time to go through everything and get a grasp on what to do, after you have done one it gets much quicker. You could also look for a used RPC, but I feel the VFD is a better option for the 1340GT due to the rapid controlled braking. Most of what you need is detailed in the enclosure document at the end of the thread for the 1340GT basic install.

As far as chucks, they all have their strength and drawbacks. A 6J scroll is often the last chuck one gets, it has the least amount of holding power and also if your stock is not perfectly round, the jaw pressure will be uneven. I guess one could always remove three of the Jaws. They are also a bit more challenging when it come to cleaning out the swarf. I would agree with David Best, and a few others that the bigger 8" scroll type chuck is a bit cumbersome and heavy. I probably would go with a 6.3" (160mm) 3J scroll and their D1-4 direct mount 8" 4J independent which will give you a lot of flexibility and cost wise is about the same as if you purchased a single 6J 8". But it is all a matter of preference. I do use an 8" Bison combination chuck which is a scroll+independent and at 85+ lbs is a bit of a beast, I have 6 chucks.

I initially tried an ER-40 holder in my chuck, but never worked that well so I made my own ER40 Set-True chuck (this was before the Shar's ER40 Zero-Set was available). When I am using collets, often my hands are very near or almost touching the chuck, I wouldn't want to have my hands anywhere near a collet holder in a jawed chuck, much safer a dedicated collet chuck which is smooth. The Shar's ER40 Zero-Set is relatively inexpensive, about $250 with a back plate. As I indicated QMT/PM was suppose to be stocking a similar 5C Set-True type for around the same price, so either one would be a good option for round stock under 1".

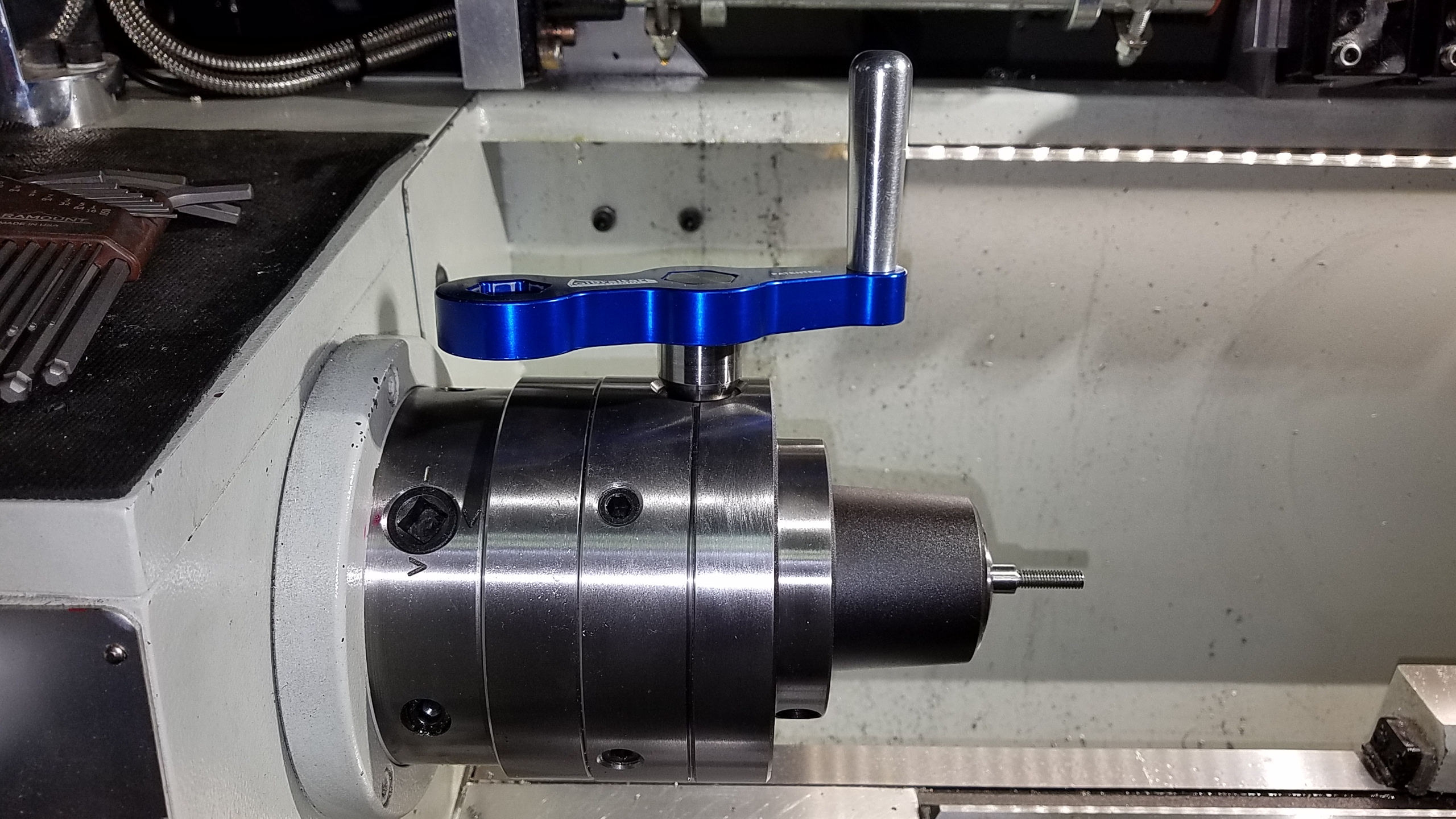

Bison 5C chuck.

To do a basic VFD install for this lathe will run around $600-700 inclusive of the VFD (WJ200-15SF), enclosure, braking resistor, power switch and wiring. Time to build out the VFD enclosure and program the VFD, figure 6-8 hours for the basics. It is straight forward wiring, but if one is not familiar with electrical wiring then takes longer and definitely have an electrician check everything before powering it up. It takes time to go through everything and get a grasp on what to do, after you have done one it gets much quicker. You could also look for a used RPC, but I feel the VFD is a better option for the 1340GT due to the rapid controlled braking. Most of what you need is detailed in the enclosure document at the end of the thread for the 1340GT basic install.

As far as chucks, they all have their strength and drawbacks. A 6J scroll is often the last chuck one gets, it has the least amount of holding power and also if your stock is not perfectly round, the jaw pressure will be uneven. I guess one could always remove three of the Jaws. They are also a bit more challenging when it come to cleaning out the swarf. I would agree with David Best, and a few others that the bigger 8" scroll type chuck is a bit cumbersome and heavy. I probably would go with a 6.3" (160mm) 3J scroll and their D1-4 direct mount 8" 4J independent which will give you a lot of flexibility and cost wise is about the same as if you purchased a single 6J 8". But it is all a matter of preference. I do use an 8" Bison combination chuck which is a scroll+independent and at 85+ lbs is a bit of a beast, I have 6 chucks.

I initially tried an ER-40 holder in my chuck, but never worked that well so I made my own ER40 Set-True chuck (this was before the Shar's ER40 Zero-Set was available). When I am using collets, often my hands are very near or almost touching the chuck, I wouldn't want to have my hands anywhere near a collet holder in a jawed chuck, much safer a dedicated collet chuck which is smooth. The Shar's ER40 Zero-Set is relatively inexpensive, about $250 with a back plate. As I indicated QMT/PM was suppose to be stocking a similar 5C Set-True type for around the same price, so either one would be a good option for round stock under 1".

Bison 5C chuck.