- Joined

- Nov 19, 2019

- Messages

- 72

I have a 833TV coming on the boat linked in the other thread and am considering my options for a DRO. On my lathe, I went with the PM DRO but I feel confident enough to install it myself. Unfortunately that really opens up the questions which one to get. I know I would love to get a graphical display and a feed rate on the display sounds like a great benefit (but may only be available on the high end options). So here are my options and questions:

1) Eason 12B got a lot of recommendations in the past. I can get it from China for about $5-600 with glass scales (w/o brackets, questionable warranty). This is similar to the price level of the basic PM option but somehow I like the idea of a graphical interface. Does that make sense or is a graphical interface not that useful? I read in one threads that the Eason can display feeds but have not seen that anywhere in the descriptions (e.g. DRO Pros) . Can somebody confirm?

2) PM's MagXact has the advantage of magnetic scales for a great price ($800) and warranty but has neither graphical interface nor feeds. How big of an advantage are magnetic scales for a hobby user in terms of durability? Is it worth the smaller dimensions e.g. for Y-travel on the 833? Apart from that it is probably the least hassle to install and come with great support.

3) EL700 via DRO Pros has all the features I want but at a high price ($1600+ with mag scales) for a hobby user. Are there other sources than DRO Pros for the system, maybe without similar responsive support. How much is support worth for a DRO?

4) Sino DRO from Aliexpress with glass scales can be had for ~$280 shipped. It gets pretty good reviews considering the price. This is seriously cheap in comparison even if I would need to replace a scale or two down the road. Or I could upgrade when I have some experience and know what I really need (want)...

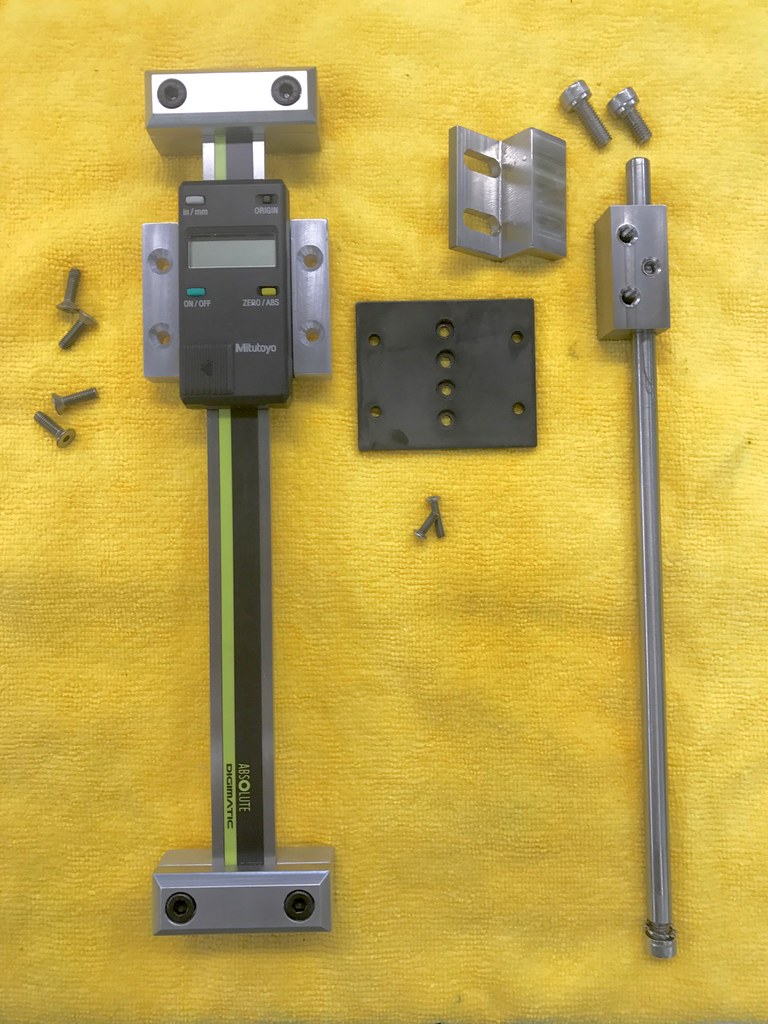

All the above assumes a 3-axis DRO setup with a separate battery operated quill DRO. Has anybody actually implemented a fourth axis for the quill on the 833? Looking at the price of a Mitutoyo scale a fourth axis is probably not ta question of cost.

I have been leaning to the Eason option for a while now (but I currently don't think I can get feeds displayed). So now I am thinking Sino for starters and invest the difference in tooling (David Best' great list implies I need to budget at least as much for tooling as for the mill..). If I don't like teh Sino DRO in use I am not out that much money after all and would have a bit more experience to judge whether the money for an EL700 is worth it to me.

Where did all the other 833 owners land on this question? What are other features should consider in comparing the DROs (e.g. "usability")?

Thanks!

Johannes

1) Eason 12B got a lot of recommendations in the past. I can get it from China for about $5-600 with glass scales (w/o brackets, questionable warranty). This is similar to the price level of the basic PM option but somehow I like the idea of a graphical interface. Does that make sense or is a graphical interface not that useful? I read in one threads that the Eason can display feeds but have not seen that anywhere in the descriptions (e.g. DRO Pros) . Can somebody confirm?

2) PM's MagXact has the advantage of magnetic scales for a great price ($800) and warranty but has neither graphical interface nor feeds. How big of an advantage are magnetic scales for a hobby user in terms of durability? Is it worth the smaller dimensions e.g. for Y-travel on the 833? Apart from that it is probably the least hassle to install and come with great support.

3) EL700 via DRO Pros has all the features I want but at a high price ($1600+ with mag scales) for a hobby user. Are there other sources than DRO Pros for the system, maybe without similar responsive support. How much is support worth for a DRO?

4) Sino DRO from Aliexpress with glass scales can be had for ~$280 shipped. It gets pretty good reviews considering the price. This is seriously cheap in comparison even if I would need to replace a scale or two down the road. Or I could upgrade when I have some experience and know what I really need (want)...

All the above assumes a 3-axis DRO setup with a separate battery operated quill DRO. Has anybody actually implemented a fourth axis for the quill on the 833? Looking at the price of a Mitutoyo scale a fourth axis is probably not ta question of cost.

I have been leaning to the Eason option for a while now (but I currently don't think I can get feeds displayed). So now I am thinking Sino for starters and invest the difference in tooling (David Best' great list implies I need to budget at least as much for tooling as for the mill..). If I don't like teh Sino DRO in use I am not out that much money after all and would have a bit more experience to judge whether the money for an EL700 is worth it to me.

Where did all the other 833 owners land on this question? What are other features should consider in comparing the DROs (e.g. "usability")?

Thanks!

Johannes