Jim, Thank you!

Yes, I realize the motor is solenoid-released, manually applied. My understanding would be that this would be useful as an E-Stop brake. If I've misunderstood, shame on me. I know it has the manual release knob which can be used (I assumed) in a pinch if I needed to run the motor, and say for instance, the solenoid had failed, so that I couldn't electrically release the brake. Did I misunderstand this? As for the spindle forward and reverse, yes, manual.

I'm waiting on Ken(but I've urged him not to rush for my sake...I know he's got other things to do, and he's already been exceedingly kind, as have you all, btw, and thank you,) because I'm more than happy to pay for the parts I'll need if he has them. Much rather get them from him if he doesn't need them then from some seller on Ebay or from an electrical parts house if he can spare them.

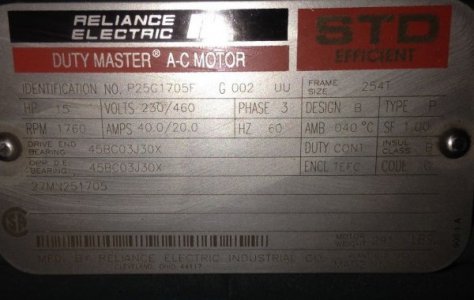

As for the motor dataplate, and also the brake dataplate, here you are:

View attachment 137521 View attachment 137522

Oh, and here's the motor. Dusty, but still unused and stored in a climate controlled storage room since it was minted:

View attachment 137523

I will start making the list.

I'll get a disconnect. The lathe will be hardwired so no need for sockets/plugs on this. You mentioned a fused disconnect specifically. Will 40amps get it here? I know the motor itself is rated at 40amps, but am I going to be drawing the whole smack? Doesn't load on the machine determine that to a fair extent? I guess I'm asking what my worst-case current demand is going to be with this. When you say "panel for the enclosure," you mean the add-on back panel? On the shopping list. I guess the ratings on the breakers I'll need for the various circuits will vary. As far as the pump outlet and lamp outlet this is supposed to have, I'd plan on 110/120v pump and lamp. I won't be buying a giant, heavy duty coolant setup unless I find that I'm really going to need it a lot more than I think I will. I was thinking something more modest. I may even try something more modest to begin with, like Kool Mist, which is air-powered. Point is, I don't see myself needing a heavy duty 3-phase coolant pump set up. Of course, the way my life goes... Realistically, I'm not going to be working at production pace by a long shot. On the other hand, if you're turning something large and doing many passes... What's your recommendation? Most of the time, my work on this lathe will skew heavily toward the lower end of its capabilities. I seriously doubt I'll ever approach even half of what it can do. I'm up for suggestions and advise on this in particular. Lamp is easy... 120v... Just probably a single bulb incandescent type. Nothing fancy. Truth is, I'm not wedded to any of these things being built into the lathe because I'll be able to add supporting circuits where I need them. The main thought I have is that the lathe was equipped with these things, so I'd like to maintain them on the lathe if feasible.

Once we sort out what I'll need, I'll check with Ken on which things he has on hand that he'd be willing to part with. Then I'll go part-shopping. Hopefully, you guys will be able to steer me from too much trouble...

Thanks Jim!

Mark