-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Why 1/2 spindle speed in Reverse

- Thread starter slow-poke

- Start date

- Joined

- Apr 30, 2015

- Messages

- 11,328

Probably for "safety" reasons. Just a guess

Does it have a threaded spindle?

Does it have a threaded spindle?

- Joined

- Jan 6, 2017

- Messages

- 1,214

My G0704s original 90v dc motor control board put out about 3/4 o it's fw speed voltage when in reverse, at the same speed setting.

If your PM uses a similar brushed dc motor, the Chinese knockoff KB controller board is probably is doing the same. I believe there are some trim potentiometers on the board that allow tuning the fw/rev voltage outputs. I'm not sure if the factory actually tunes the boards after installing them or not.

I swapped my motor out with a 1.5hp bldc a log time ago, so I don't remember exactly how to do it.

If you look up the KB120 manual, you can probably figure it out. On mine, I seem I remember the stock board being so identical to the KB120 that it had the same trim pots, capacitors, plugs and everything in the same places. It was a blatant copy.

If your PM uses a similar brushed dc motor, the Chinese knockoff KB controller board is probably is doing the same. I believe there are some trim potentiometers on the board that allow tuning the fw/rev voltage outputs. I'm not sure if the factory actually tunes the boards after installing them or not.

I swapped my motor out with a 1.5hp bldc a log time ago, so I don't remember exactly how to do it.

If you look up the KB120 manual, you can probably figure it out. On mine, I seem I remember the stock board being so identical to the KB120 that it had the same trim pots, capacitors, plugs and everything in the same places. It was a blatant copy.

Last edited:

- Joined

- Oct 24, 2013

- Messages

- 481

Ahhhh, maybe too much beer!

Our controllers are KBMG212D and NOT KB120, these have separate fwd and rev current limiting and a piggy-backed board for multi-speed operation in both directions. Sorry, I know this does not help you at all!

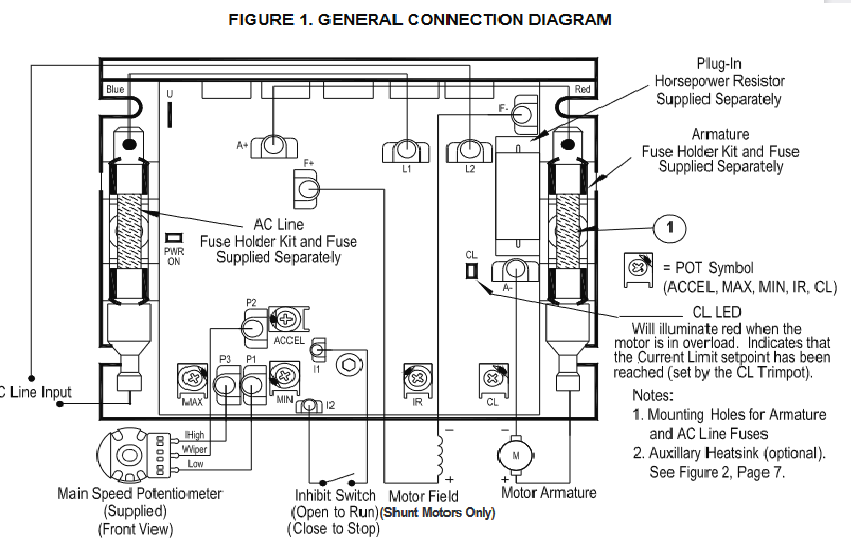

Here's the KB120 board layout nonetheless:

Our controllers are KBMG212D and NOT KB120, these have separate fwd and rev current limiting and a piggy-backed board for multi-speed operation in both directions. Sorry, I know this does not help you at all!

Here's the KB120 board layout nonetheless:

Last edited:

I’m adding CNC capability to my lathe, as part of that I had to figure out how to allow the CNC controller to control the motor while allowing the original controls to operate as they did when not in CNC mode. I now have that circuit worked out and discovered the 1/2 speed aspect while doing so and don’t understand why they reduce the speed in reverse.

Figuring out an appropriate circuit was straightforward once I corrected all the errors in the supplied wiring diagram. the provided wiring diagram appeared at first superficial glance to be correct. In reality the diagram could not be more misleading than it was, for example:

1) the H & N were swapped

2) the filter unit was shown before the start/stop and it was actually after

3) the F-O-R switch indicated that the contacts for 1/2 speed would be closed in both F & R

the list goes on….

The 1/2 speed connection is simple, when in reverse a contact closes that parallels a pot on the filter board (A & B connections ) with the lower two connections of the front panel pot, lowering the speed while in reverse.

My question is why do they do that?

Figuring out an appropriate circuit was straightforward once I corrected all the errors in the supplied wiring diagram. the provided wiring diagram appeared at first superficial glance to be correct. In reality the diagram could not be more misleading than it was, for example:

1) the H & N were swapped

2) the filter unit was shown before the start/stop and it was actually after

3) the F-O-R switch indicated that the contacts for 1/2 speed would be closed in both F & R

the list goes on….

The 1/2 speed connection is simple, when in reverse a contact closes that parallels a pot on the filter board (A & B connections ) with the lower two connections of the front panel pot, lowering the speed while in reverse.

My question is why do they do that?

- Joined

- Apr 30, 2015

- Messages

- 11,328

Perhaps the design was done for lathes with threaded spindles to prevent the chuck from loosening in reverse

That's my spill, anyhow.

You can certainly defeat the 1/2 speed contact if you don't see that as a possibility

One thing I would caution against is changing the direction switch under power, you could damage the KB output stage

-M

That's my spill, anyhow.

You can certainly defeat the 1/2 speed contact if you don't see that as a possibility

One thing I would caution against is changing the direction switch under power, you could damage the KB output stage

-M

I will, I developed a simple to use low cost touchscreen controller that lets you automate basic things like turning and threading. I will post details when fully tested.Very interested in your CNC Lathe build. Hoping you document it on the forum. Good luck!