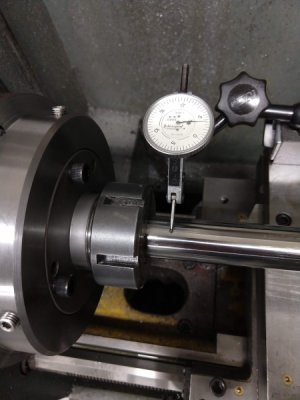

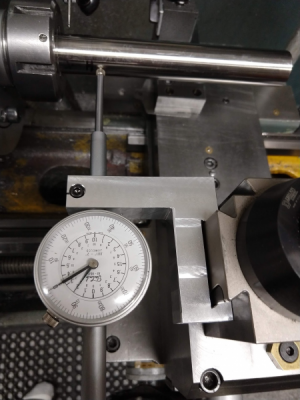

I had an issue on a new D1-4 face plate that was kind of a non-repeatable misfit every time I mounted it. Turns out the nose taper was just a smidge small relative to the spindle nose. So even though the cam locks were pulling it inward & felt tight, it was kind of bottoming out prematurely. Clue was a tiny gap between the spindle face. Backplat mounts are kind of a tricky precision fit, it has to engage the taper with no slop but also snug to the boss flange. Not either/or but both. Once I blued the surfaces I could see what was going on. So some careful lapping using a dummy arbor brought it into tune. You might have something related to the tru-turn screws but this would supersede it so worth checking.

Last edited: