- Joined

- Dec 23, 2019

- Messages

- 176

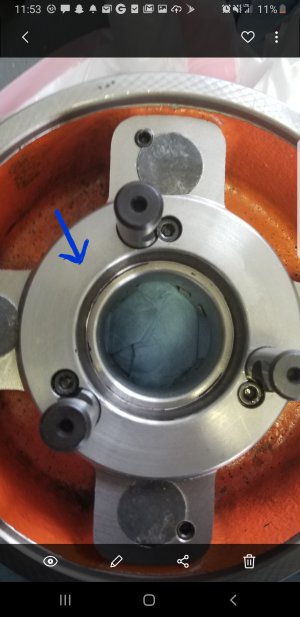

Yessir that was the next option if whoopee suggestion doesnt show similar numbers. I have zilch experience sanding chucks to fit spindles so I'm worried if I take too much off and screw it up in the opposite direction I'll have no chance of a refund. Im pretty confident with sanding metal though I do have experience with sanding non critical stuff.