- Joined

- Nov 28, 2016

- Messages

- 2,356

I have just purchased an old Smith & Mills 20" shaper.

It has two motors on it... the main motor is a 5hp GE 220/440 3 phase. The smaller motor is a 1hp Howell Electric 220/440 3 phase... the smaller motor only drives the rapid traverse on the cross slide.

There are two Allen-Bradley contactors... I would assume one powers the main motor and keeps it running until it is turned off... the other powers the rapid motor and is a momentary switch. Both contactors appear to be identical.

Question 1: on the tags on the contactors the block labeled 'control voltage' is blank... the block labeled 'voltage' has 220 stamped in it. The block labeled 'amps' is also blank. Both have N36 thermal elements. What should the control voltage be, 220v?

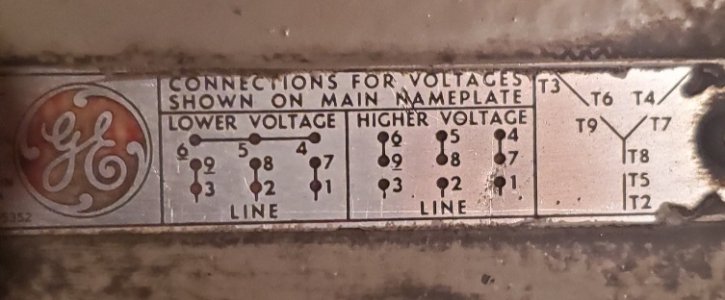

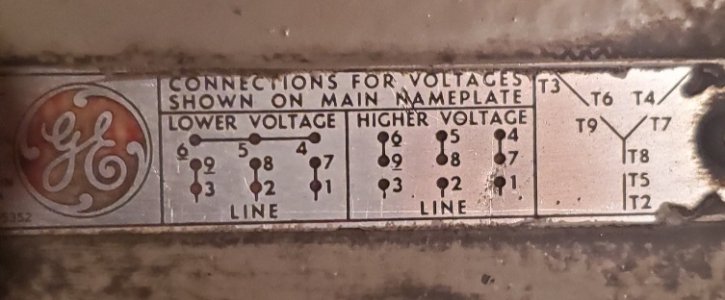

Question 2: the seller told me that the machine was wired for 440v... but just looking at the diagrams on both motors, I'm not sure about that. I can't find any numbers on the wires, but looking at this tag...

...it looks like the lower voltage would have 4 sets of 3 wires connected, while the high voltage would have 6 sets of 2 wires connected. The diagrams for both motors are the same, and both motors have 4 sets of 3 wires connected... am I assuming too much?

Question 3: would this machine be too much to run on a 7-½hp RPC?

Question 4: are the thermal elements (heaters?) adequate for 220v service? The main motor tag states 13.7 FLA at 220v... the rapid motor tag says 3.18 amps at 220v...

Thanks- Bear

It has two motors on it... the main motor is a 5hp GE 220/440 3 phase. The smaller motor is a 1hp Howell Electric 220/440 3 phase... the smaller motor only drives the rapid traverse on the cross slide.

There are two Allen-Bradley contactors... I would assume one powers the main motor and keeps it running until it is turned off... the other powers the rapid motor and is a momentary switch. Both contactors appear to be identical.

Question 1: on the tags on the contactors the block labeled 'control voltage' is blank... the block labeled 'voltage' has 220 stamped in it. The block labeled 'amps' is also blank. Both have N36 thermal elements. What should the control voltage be, 220v?

Question 2: the seller told me that the machine was wired for 440v... but just looking at the diagrams on both motors, I'm not sure about that. I can't find any numbers on the wires, but looking at this tag...

...it looks like the lower voltage would have 4 sets of 3 wires connected, while the high voltage would have 6 sets of 2 wires connected. The diagrams for both motors are the same, and both motors have 4 sets of 3 wires connected... am I assuming too much?

Question 3: would this machine be too much to run on a 7-½hp RPC?

Question 4: are the thermal elements (heaters?) adequate for 220v service? The main motor tag states 13.7 FLA at 220v... the rapid motor tag says 3.18 amps at 220v...

Thanks- Bear

Last edited: