- Joined

- Nov 27, 2022

- Messages

- 108

Hello everyone, hope you all are well.

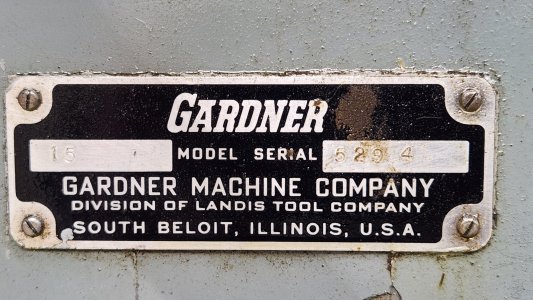

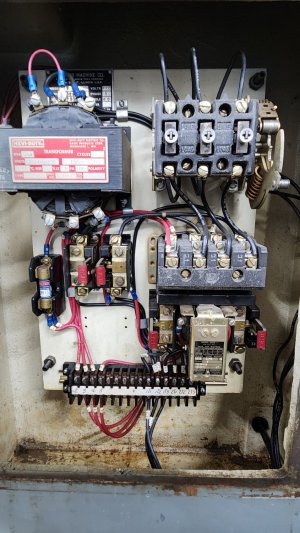

Got a new machine the other day! When I was looking under her skirt I noticed there is no ground wire into the panel. Just the three phases coming from the junction box where the plug will be wired. Where/how would I add a ground to this panel? Let me know if you need better pictures and thanks in advance!

M. Noob

Got a new machine the other day! When I was looking under her skirt I noticed there is no ground wire into the panel. Just the three phases coming from the junction box where the plug will be wired. Where/how would I add a ground to this panel? Let me know if you need better pictures and thanks in advance!

M. Noob