- Joined

- Mar 3, 2017

- Messages

- 744

Generally, you want every enclosure with AC power inside to pass a ground-bond test at currentThank you. Will do. And if I don't get very low resistance...?

levels high enough to blow a fuse, when certifying a design, unless 'double-insulated' rules are

used.

That doesn't mean ALL metal parts (handles, etc) need ground testing,

because the AC power is elsewhere. On occasion, even the rotors of motors

need grounding (because grounding the case grounds the stator, but the rotors

are not if the bearings aren't in close electrical contact) but that's an odd

application-dependent variation.

The case of a motor should be grounded, the shaft needn't be tested.

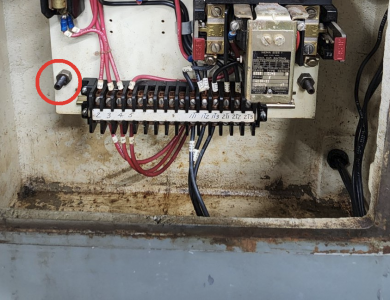

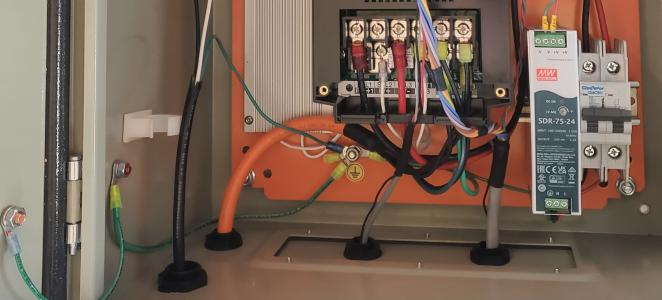

I'm slightly shocked that the depicted control panel box doesn't have any visible green/yellow wire,

or designated ground-connect post or busbar.