That depends on the voltage transformer that's used on the lathe. The transformer on my mill has 110V & 220V inputs which is consistent of it's specs, can run on either. My lathe on the other hand is not listed as being capable on running on 110V. Sure enough, the transformer on my lathe only has inputs for 220V & higher, no 110V input.

Now that the OP has stated it had a 110V plug on it who knows, but then again someone could have cared less & wired up a NEMA 5-15 outlet for 220V. Best thing to do is look at the transformer inside the control panel & see what inputs voltages it supports.

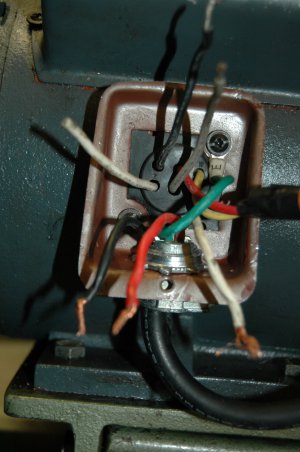

I went out to my shop and looked more carefully at the wiring and contrary to what "Busy Bee" said, it can be run as 110 or 220V. I took some pictures of the wiring on the lathe. Maybe this will make more sense to someone else.