-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wm210v threading gears

- Thread starter weston1968

- Start date

- Joined

- Aug 29, 2016

- Messages

- 121

I have updated the program to version 6. I have also included a spreadsheet that has all of the valid gear combinations for imperial threads and the error %. This was calculated by my program. The gears have not yet come in but they should fit.Threading - Google Drive

drive.google.com

This is a basic program to calculate the best gears for use on the Chinese lathes. I have ordered a wm210v. I have ordered both the imperial gears and metric gears used in the program. You can add or subtract any gears.

The program does not check fit of the gears but gives many possibilities. It shows both the imperial and metric thread at the same time. I used this for my Logan lathe and stripped it down for the WM210V.

My assumptions are spindle gear 56T and Feed is shaft thread 1.5mm.

Link for all is in the first post.

I like the program, I'm just having trouble understanding the the gear posistion, maybe I'm over analyzing it. Trying to make 24 tpi... I got the 55 spindle but it's the 33Tover 20T 80T under 60T that I'm trying to figure... I can fit 3 separate rows of gears under the spindle. I'm sure I'm missing something simple, any help would be appreciated.

56

33 20

60 80 ?

56

33 20

60 80 ?

- Joined

- Aug 29, 2016

- Messages

- 121

I do not know which gears you have but the results should have looked like:I like the program, I'm just having trouble understanding the the gear posistion, maybe I'm over analyzing it. Trying to make 24 tpi... I got the 55 spindle but it's the 33Tover 20T 80T under 60T that I'm trying to figure... I can fit 3 separate rows of gears under the spindle. I'm sure I'm missing something simple, any help would be appreciated.

56

33 20

60 80 ?

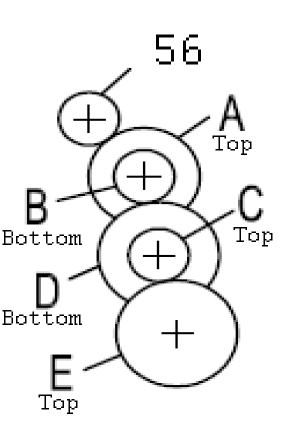

56 Spindle Top -> 35 Top over 40 Bottom -> 72 Bottom under 50 Top -> 84 Top; 0.0125% Error 24.003 Imperial 1.0582 Metric 140.5 LS Center -> End of Gear Frame 159.0 Spindle OD -> LS Center

Where 56 is the spindle gear which drives the 35T gear which is over the 40T gear which drives 72T gear which is under the 50T gear which drives the 84T on the lead screw

Gotcha. I think where I threw myself off was the over/under part, where "over" being the outside gear furthest to the left & "under" being the inside gear furthest to the right on each quadrant....(AB) (CD) (EF)......I was physically putting the gear over/on top of the next gear, ill try it again, much appreciated.I do not know which gears you have but the results should have looked like:

56 Spindle Top -> 35 Top over 40 Bottom -> 72 Bottom under 50 Top -> 84 Top; 0.0125% Error 24.003 Imperial 1.0582 Metric 140.5 LS Center -> End of Gear Frame 159.0 Spindle OD -> LS Center

Where 56 is the spindle gear which drives the 35T gear which is over the 40T gear which drives 72T gear which is under the 50T gear which drives the 84T on the lead screw

- Joined

- Aug 29, 2016

- Messages

- 121

"over" means the gear on top of the gear "under" on the same post.

A 35T, B 40T, D 72T, C 50, E 84

A 35T, B 40T, D 72T, C 50, E 84

Last edited:

Good work Weston. For reference, this is the gear calc program that I wrote based on previous work.

https://www.hobby-machinist.com/threads/new-lathe-change-wheels-calculator.96600

A single file, open-source solution which runs in the browser, so you can use it on your mobile while setting up the lathe.

It does calculate gears fitting between spindle and leadscrew, but not possible interference with the quadrant cover.

It supports any lathe with easy to enter parameters, which are stored and modified at will.

All metric and imperial combinations of lead screw and desired work are supported.

The complete table of possible threads is available.

https://www.hobby-machinist.com/threads/new-lathe-change-wheels-calculator.96600

A single file, open-source solution which runs in the browser, so you can use it on your mobile while setting up the lathe.

It does calculate gears fitting between spindle and leadscrew, but not possible interference with the quadrant cover.

It supports any lathe with easy to enter parameters, which are stored and modified at will.

All metric and imperial combinations of lead screw and desired work are supported.

The complete table of possible threads is available.

- Joined

- Aug 29, 2016

- Messages

- 121

Good work Weston. For reference, this is the gear calc program that I wrote based on previous work.

https://www.hobby-machinist.com/threads/new-lathe-change-wheels-calculator.96600

A single file, open-source solution which runs in the browser, so you can use it on your mobile while setting up the lathe.

It does calculate gears fitting between spindle and leadscrew, but not possible interference with the quadrant cover.

It supports any lathe with easy to enter parameters, which are stored and modified at will.

All metric and imperial combinations of lead screw and desired work are supported.

The complete table of possible threads is available.

- Joined

- Aug 29, 2016

- Messages

- 121

That is a really nice program. I have moved on to an ELS because I need to cut threads right up to a shoulder. It also lets me cut any random thread. With a MT5 taper in the head stock I can use 5C collets. My WM210V with ELS and variable speed is mechanically so so, but versatile and more useful than my more accurate Logan 200 with its change gear box.

So did the guy which originally wrote my program. Now that ELS is accessible and even available on a new mini lathe, it's no doubt the way to go.I have moved on to an ELS because I need to cut threads right up to a shoulder.

I have got a 5C chuck and collects. for my 250mm lathe, but not fitted them yet. Of course the small 26mm bore will remain a bit of a limitation.It also lets me cut any random thread. With a MT5 taper in the head stock I can use 5C collets.

I think one can't expect much from the 210mm (or even 220mm now) lathes with a 100mm bed width, and all other small parts. Now coming with 1.1kW BLDC motor and 125mm chuck which are too big for the infrastructure. Attractive on paper, and cheap to buy, but not right for work of some size and precision, my opinion at least.My WM210V with ELS and variable speed is mechanically so so, but versatile and more useful than my more accurate Logan 200 with its change gear box.

Last edited: