- Joined

- Aug 5, 2013

- Messages

- 125

Nice. What are they 25x100's?

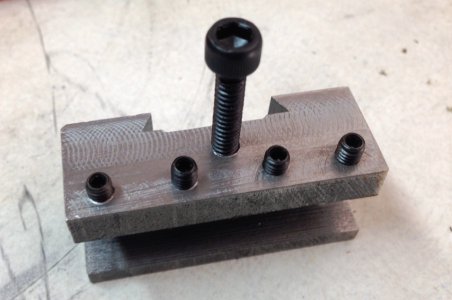

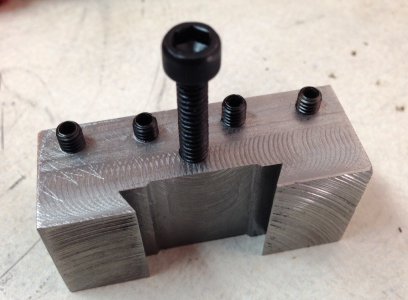

I made a cantilever mount and tripod for mine.

Gave me a fabulously stable view.

View attachment 87840

Ignore the concrete block, it used lead weights in the final version.

Those are 25x70's. The GF and I have been going out to the Las Vegas Astronomical Society's Star Gazing events. You get spoiled by the 20" Dobsonian telescopes on Equatorial tables or the 5" and 8" telescopes with cameras taking 10 second exposures. These guys are really capturing some incredible images, despite the awful light pollution here in Las Vegas.