- Joined

- Feb 8, 2014

- Messages

- 11,144

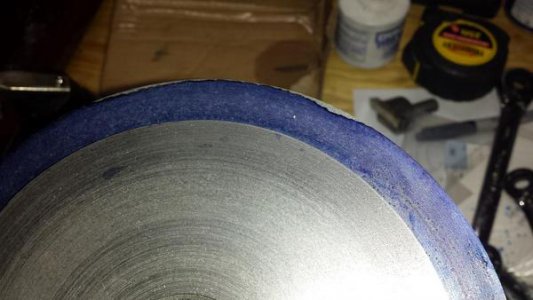

Here is a curious question: Do you think anybody could pull this one by hand and still obtain similar results? I will even allow the use of a rotary table ;-)

That's pretty, nice lines.

I could do it on a rotary table, but it would be a lot of work. I find myself designing much more complex shapes since I bought my CNC. Back in the hand crank days (not that long ago), I kept things pretty simple.