- Joined

- Dec 27, 2014

- Messages

- 4,059

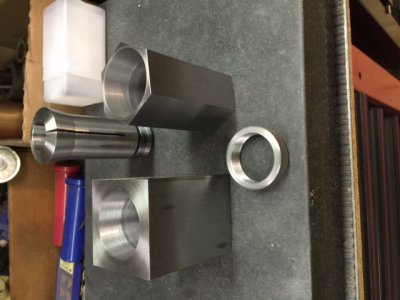

I've been working for two months (accumulating equipment, making errors, etc.) and finally have my X drive complete on my PM25. The power is from a auto window drive, 12 volt from a battery charger, through a Chinese variable [something]. slow speed is one Inch per minute, fast is seven I/M. I don't have a rapid, but it sure beats cranking.

I've still gotta cover the belt/pulley.

I've still gotta cover the belt/pulley.