- Joined

- Jan 20, 2013

- Messages

- 132

Got a good bit of shop time this weekend. Started on Saturday with an extension for the quill hand wheel on my mill. When I got it the hand wheel was missing. I ordered a new one and realized why the other guy probably never used it - the quill encoder for the ProtoTRAK interferes with it! I rummaged around my scrap bin but didn't have any rounds in 1 1/4" diameter. I finally found an unknown steel scrap that was close. It was a complete pain to machine. Super hard, flaky chips, not like cast but almost like a magnet. Weird stuff. Anyway, my mini lathe wouldn't touch it and my Clausing lathe isn't running, so I milled the diameter and punched some holes in it. Not pretty, but it works.

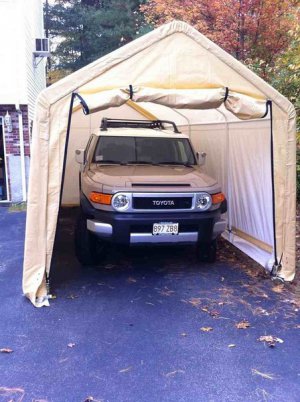

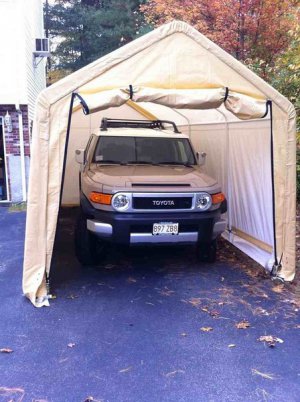

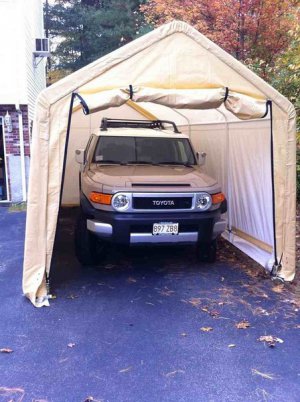

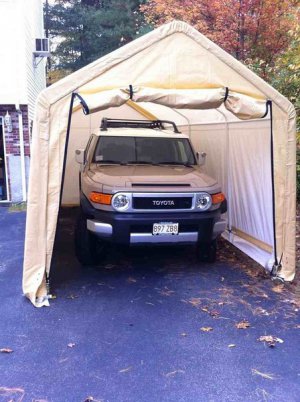

Finished Saturday by picking up our new FJ cruiser and erecting a Harbor Freight garage for it!

Today I whipped up some table covers for the mill using some MDF I had lying around.

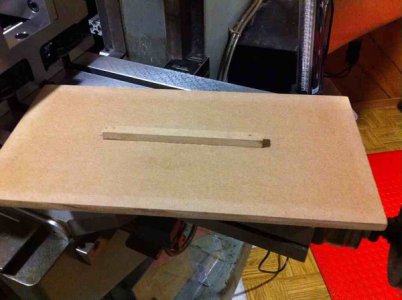

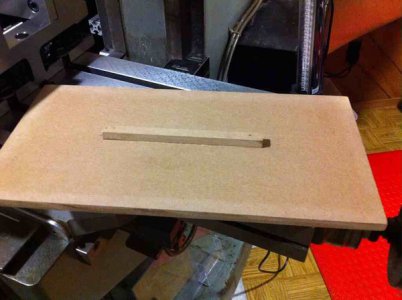

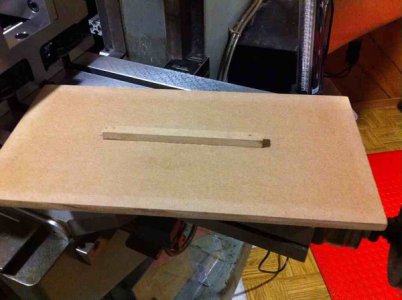

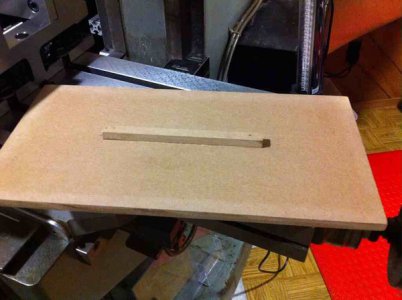

Finally, I moved in my new to me surface plate I got at an auction a couple of weeks ago. It's been sitting in the garage since then, and it was time to get it moved. It's a 18" x 24" x 4" Starrett crystal pink. Heavy beast! That's a 6" dial caliper for reference.

Sorry for the long post - had a bunch of pics and thought I'd share.

Finished Saturday by picking up our new FJ cruiser and erecting a Harbor Freight garage for it!

Today I whipped up some table covers for the mill using some MDF I had lying around.

Finally, I moved in my new to me surface plate I got at an auction a couple of weeks ago. It's been sitting in the garage since then, and it was time to get it moved. It's a 18" x 24" x 4" Starrett crystal pink. Heavy beast! That's a 6" dial caliper for reference.

Sorry for the long post - had a bunch of pics and thought I'd share.