Hello everyone

I haven't posted in a while so today I decided to take a few pics and show what I'm up to.

I have a 1978 Honda Express, that for years I would not ride because it was too slow. When it was new it's advertised top speed was 25mph and it is 49cc/50cc.

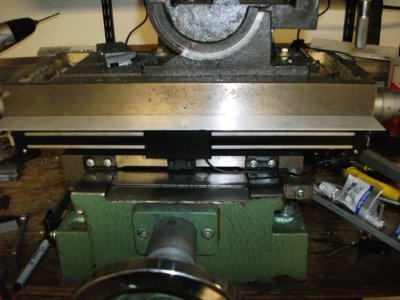

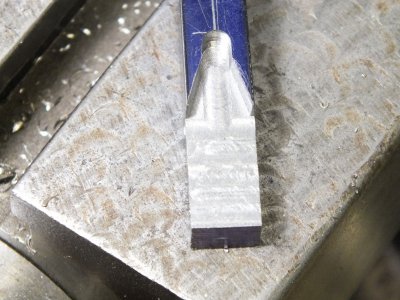

So I took all the original parts off (and stored them away) and started buying and making what I needed to get some speed. first I added a expansion chamber exhaust and a little bigger carb.... 35mph. then I added a 70cc cylinder kit and the speed went to 40mph. but the engine was turning 14,000 rpm no good. so I found an 1981 2 speed Honda express II engine same problem 14,000 at 40 but it gets there a lot faster. so I disassembled the transmission and found there was room to change the primary chain sprocket, great idea but Honda uses a proprietary chain size, I had to make my own sprocket and I changed from 30tooth to 27tooth. hit 47mph but motor was getting hot. So then I converted a Puch head to fit but still fighting lean mixture heating. re-jet carb, no jets available from china lol I knew the price was too good.

I ordered a new flat slide 24mm oko carb and jet kit, be here Monday.

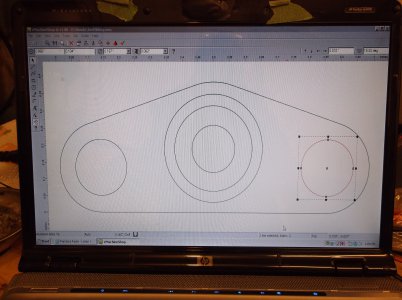

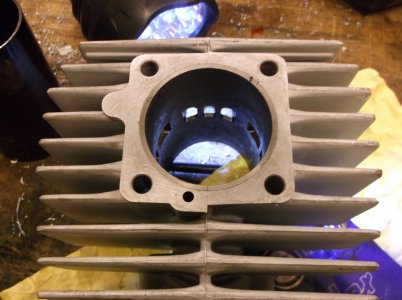

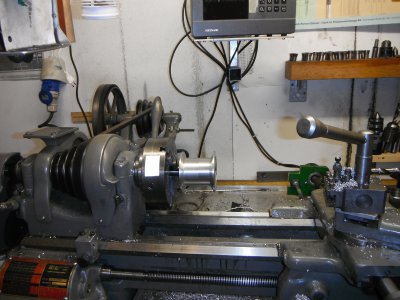

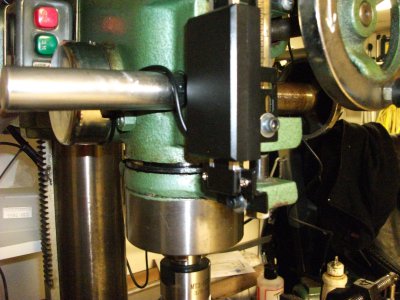

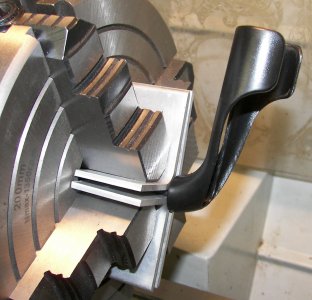

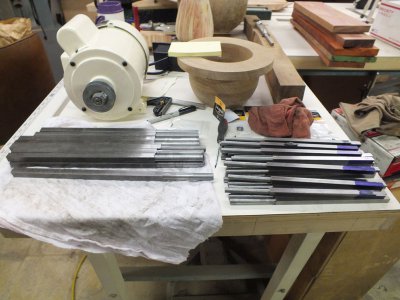

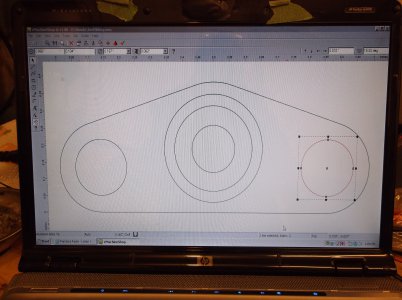

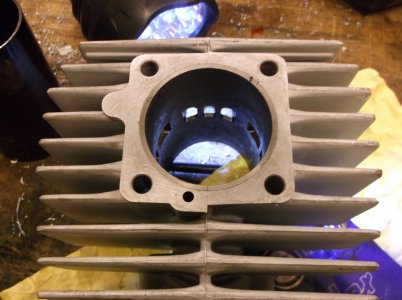

so since 46mm 70cc was the biggest cylinder available for this scooter I decided to make my own cylinder. I had a bad aluminum cylinder to bore oversize. I found a sleeve for a 1957 Honda Benly motorcycle that would work and A 50mm piston for a stihl ms440 chainsaw. the parts arrived Saturday afternoon and I started working today. first I built a boring jig for the cylinder and bored out the old liner to fit the oversize one. then I mapped out the port layout for the timing I wanted and milled the ports into the sleeve/liner. I went with a .004 fit and locktite permanent bearing mount. I heated the cylinder and the liner slid right in with the press. I knurled the top of the liner for a lock fit.

my ports matched up well and I have a lot of port matching to do yet because mine are larger and A different design/shape. my new piston Is half the weight and 8mm shorter so I'm stroking the engine and decking off 3.6mm from the top of the cylinder.

I know this is crazy, but I think of it this way, imaging trying to "double" the top speed of your car. It used to do 120 now it does 240.

that's what i'm doing, doubling the top speed. from 25mph to 50mph+.

I now have 4 0f these motors 3 to play with and the original packed away If I restore the bike to original it's 90% complete.

these are the pics of the work I did today and a few pics of making a carb part a while back.

thanks for viewing

steve