- Joined

- Jan 2, 2014

- Messages

- 8,852

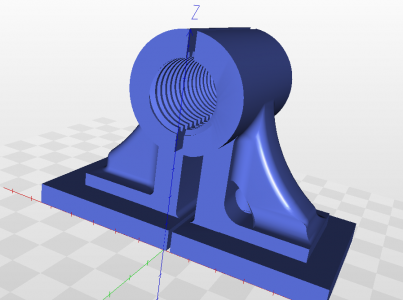

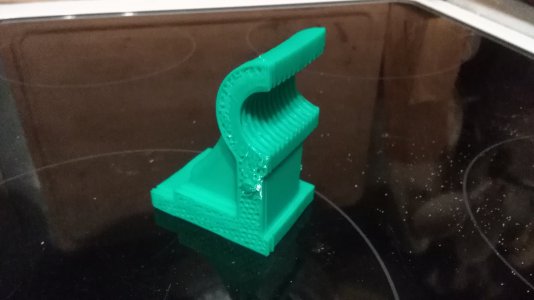

I think I may try to create a 3d model for the half nuts and 3d print a set in ABS............................. I have nothing to lose so it must be worth a try.

Please let us know how that works out!

-brino

I think I may try to create a 3d model for the half nuts and 3d print a set in ABS............................. I have nothing to lose so it must be worth a try.